New articles published at FunGlass

We would like to draw your attention to the new papers of our researchers presenting their research results achieved in collaboration with the colleagues from FunGlass partners´ institutions. The papers are published in peer-reviewed and highly cited journals:

Sharifianjazi- M. Moradi- N. Parvin- A. Nemati- A. Jafar Rad- N. Sheysi- A. Abouchenari- A. Mohammadi- S. Karbasi- Z. Ahmadi- A. Esmaeilkhanian- M. Irani- A. Pakseresht- S. Sahmani- M. Shahedi Asl: Magnetic CoFe2O4 nanoparticles doped with metal ions: A review. In: Ceramics International, 2020, Volume 46, Issue 11, Part B, p. 18391-18412.

Sharifianjazi- M. Moradi- N. Parvin- A. Nemati- A. Jafar Rad- N. Sheysi- A. Abouchenari- A. Mohammadi- S. Karbasi- Z. Ahmadi- A. Esmaeilkhanian- M. Irani- A. Pakseresht- S. Sahmani- M. Shahedi Asl: Magnetic CoFe2O4 nanoparticles doped with metal ions: A review. In: Ceramics International, 2020, Volume 46, Issue 11, Part B, p. 18391-18412.

https://doi.org/10.1016/j.ceramint.2020.04.202

Abstract: Ceramic-magnetic nanoparticles (CMNPs) are attracting attention due to their various applications, especially in biomedical industries. Among them, spinel ferrite CMNPs have received considerable deliberations among different spinel metal oxides due to their fascinating characteristics. Spinel ferrite CMNPs are used for enhancement of the applicability of CMNPs without affecting the intrinsic advantages of iron oxide CMNPs. Spinel ferrites with doping agents have useful electrical and magnetic properties in various fields. Moreover, the replacement of metallic atoms in ferrites is promising to manipulate physical characteristics and improve their performance. Among different spinel ferrites, CoFe2O4 nanoparticles are the most investigated CMNPs. Furthermore, they are used as permanent magnets, magnetic recorders in high-density and micro-wave devices, and magnetic fluids. This study reviews the CoFe2O4 nanoparticles doped with various elements and their applications in various fields.

A.H.Paksereshta- A.Kimiayi- M.Alizadeh- H.Nuranian- A.Faeghinia: Microstructural study and hot corrosion behavior of bimodal thermal barrier coatings under laser heat treatment. In: Ceramics International, 2020, Volume 46, Issue 11, Part B, p. 19217-19227

A.H.Paksereshta- A.Kimiayi- M.Alizadeh- H.Nuranian- A.Faeghinia: Microstructural study and hot corrosion behavior of bimodal thermal barrier coatings under laser heat treatment. In: Ceramics International, 2020, Volume 46, Issue 11, Part B, p. 19217-19227

https://doi.org/10.1016/j.ceramint.2020.04.259

Abstract: In this study, nanostructured YSZ powders were deposited on the Hastalloy X Superalloy substrate coated with a metallic bond coat by plasma spraying to produce a nanostructured thermal barrier coating with bimodal microstructure. After that, the coated samples were heat-treated using a Nd:YAG laser. Then, the microstructures of the conventional and nanostructured TBCs before and after the laser glazing process were examined using a scanning electron microscope (SEM). The coating phases were studied by X-ray diffractometry (XRD). The high-temperature corrosion behavior of the nanostructured plasma sprayed coating in the presence of Vanadium pentoxide and Sodium sulfate molten salt was compared with that of the conventional coatings before and after laser treatment at 1050 °C. The hot corrosion results showed that the coatings had a similar degradation mechanism based on which the corrosive molten salt reacted with the stabilizer of YSZ, producing hot corrosion products such as YVO4. It led to an unwanted phase transformation from tetragonal (t) to monoclinic (m) Zirconia and the final degradation of the TBC system. However, reducing molten salt penetration, decreasing surface roughness and, reduction of the specific surface area are three important mechanisms that improved hot corrosion resistance, finally extending the lifetime of the glazed samples. The results also showed that the nanostructured TBC had higher hot corrosion resistance in comparison with other samples.

Sharifianjazi, F., Pakseresht, A. H., Shahedi Asl, M., Esmaeilkhanian, A., Nargesi khoramabadi, H., Won Jang, H., & Shokouhimehr, M.: Hydroxyapatite Consolidated by Zirconia: Applications for Dental Implant. In: Journal of Composites and Compounds, 2020, 2(2), 26-34.

Sharifianjazi, F., Pakseresht, A. H., Shahedi Asl, M., Esmaeilkhanian, A., Nargesi khoramabadi, H., Won Jang, H., & Shokouhimehr, M.: Hydroxyapatite Consolidated by Zirconia: Applications for Dental Implant. In: Journal of Composites and Compounds, 2020, 2(2), 26-34.

https://doi.org/10.29252/jcc.2.1.4

Abstract: Zirconia has garnered significant attention as a new ceramic material for dental implant due to its excellent biocompatibility, strength, and promoting the oral rehabilitation with high aesthetic, biological and mechanical properties. It also expedites the amelioration of bone minerals surface by its bio-integrative ingredients which are naturally close to ceramic intrinsic of bone. Alternatively, hydroxyapatite (HAp) has prevalently been used in dental implant due to its high biocompatibility. However, it generally shows weak strength and mechanical properties. Consequently, incorporating zirconia and HAp produces appropriate composites for dental implant having improved physiochemical properties. This review provides discussions addressing the methodologies and exemplars for the designed composites used in dental implant applications. The representative methods for surface modification of zirconia incorporating HAp (i.e. sol-gel, hot isostatic pressing, plasma spraying, electrophoretic deposition, etc.) is highlighted. The advantages, disadvantages, biocompatibility, strength, and osseointergration and biointegration properties of the presented composites are explored.

M. Parchovianský- I. Petríková- P. Švančárek- M. Lenz Leite- G. Motz- D. Galusek: Passive filler loaded polysilazane‐derived glass/ceramic coating system applied to AISI 441 stainless steel, part 2: Oxidation behavior in synthetic air. In: International Journal of Applied Ceramic Technology. 2020 Volume 17, Issue 4, p. 1675-1687.

M. Parchovianský- I. Petríková- P. Švančárek- M. Lenz Leite- G. Motz- D. Galusek: Passive filler loaded polysilazane‐derived glass/ceramic coating system applied to AISI 441 stainless steel, part 2: Oxidation behavior in synthetic air. In: International Journal of Applied Ceramic Technology. 2020 Volume 17, Issue 4, p. 1675-1687.

https://doi.org/10.1111/ijac.13531

Abstract: This article features the oxidation behavior of ferritic stainless steel grade AISI 441 coated with protective polymer‐derived ceramics (PDC). Two PDC compositions are studied with respect to their oxidation resistance in a flow‐through atmosphere of synthetic air at temperatures of up to 1000°C. The coatings contain a combination of six passive fillers: Y‐containing ZrO2, glass microspheres, alumina‐yttria‐zirconia (AYZ) powder, and three commercial glasses. They are pyrolyzed in air for 1 hour at 800°C with heating and cooling rates of 3 K/min. Detailed microstructural examination of the oxide products formed at the surface of samples after exposure to air at 900°C, 950°C, and 1000°C for 1‐48 hours is analyzed. Both uncoated steel and steel coated with two of the protective systems described in part 1 of this article are investigated. Fe, Cr2O3, TiO2, and a spinel of the composition (Mn,Cr)3O4 are identified at the oxidized surface of the steel substrate using X‐ray diffraction. A significant weight gain of the unprotected steel is measured after all experiments, while oxidation tests of the coated steel show a negligible weight gain after 900°C and 950°C. During the early stages of coating oxidation, the monoclinic‐to‐tetragonal ratio in the zirconia filler is shifted toward the monoclinic modification. Longer exposures and higher temperatures lead to the formation of yttrium aluminum garnet (YAG) due to glass microsphere crystallization and solid state reactions in the AYZ powder. The crystallization of the three commercial glasses functioning as sealants leads to the formation of Ba(AlSiO4)2 also known as hexacelsian, which subsequently transforms to celsian. YZr8O14 is also formed. The protective effect of the PDC coatings applied to the stainless steel is demonstrated up to 950°C.

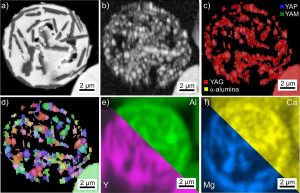

Wisniewski, W., Švančárek, P., Prnová, A., Parchovianský M., Galusek, D.: Y2O3–Al2O3 microsphere crystallization analyzed by electron backscatter diffraction (EBSD). In: Sci Rep 10, 11122 (2020)

Wisniewski, W., Švančárek, P., Prnová, A., Parchovianský M., Galusek, D.: Y2O3–Al2O3 microsphere crystallization analyzed by electron backscatter diffraction (EBSD). In: Sci Rep 10, 11122 (2020)

https://doi.org/10.1038/s41598-020-67816-7

Abstract: The crystallization of glass microspheres in the Y2O3–Al2O3-system produced from precursor powders of four different nominal compositions via flame synthesis is analyzed in detail by electron microscopy with a focus on electron backscatter diffraction (EBSD). Growth models are formulated for individual microspheres crystallized during flame synthesis as well as after an additional heat treatment step. 16 different types of crystallized bodies are cataloged for future reference. They are presented without regard for their relative occurrence; some are extremely rare but illustrate the possibilities of flame synthesis in the analyzed system. All three phases in the binary Y2O3–Al2O3-phase diagram (Y3Al5O12, YAlO3 and Y4Al2O9) and α-alumina are located by EBSD. Energy dispersive X-ray spectrometry results obtained from these microspheres show that their chemical composition can deviate from the nominal composition of the precursor powder. The multitude of differing microsphere types showing polygon and dendritic crystal growth as well as phase separation indicate that flame synthesis can lead to a wide variety of parameters during microsphere production, e.g. via irregular flight paths through the flame, contaminants or irregular cooling rates.