Biological testing laboratory of materials

| Biological Safety Cabinet HERAsafe |

| Function and use: |

| Class II laminar box for protection of operators, environment and products when working with active and toxic materials, tissue cultures, media preparation and handling of pathogenic material. Allows for easy cleaning and sterilization in an autoclave, equipped with electrical outlets for connecting equipment used in the box and an electrically operated pull-out window. Height-adjustable pedestal under the box allowing ergonomic work while seated, UV lamp to sterilize the environment and safety flame with sensor switching. |

| Technical specification: |

| an internal volume of at least 110 litres, – an internal sealed transparent door for visual inspection of samples without alteration of the internal environment, – 1 socket in the chamber for the connection of equipment located in the incubator, – microprocessor-based temperature control with a minimum temperature range of +5 °C to +70 °C with display, adjustment in increments of 0,1 °C, – forced air circulation |

| Model: |

| Thermo Fisher HERAsafe 2030i Biological Safety Cabinet |

| Responsible Personnel: |

| Zuzana Neščáková <zuzana.nescakova@tnuni.sk> |

| CO2 incubator Heracell Vios – Controlled atmosphere cell culture device |

| Function and use: |

| A controlled atmosphere device for the cultivation of cell and tissue cultures under defined conditions of temperature, humidity and gas pressure. |

| Technical specification: |

| Chamber capacity 150 l, – programmable acoustic and visual alarms: water level, door open, % CO2, RH, T °C, – CO2 atmosphere control option – selectable CO2 content from 0% to 20% with a sensitivity of 0.1%, – ability to maintain constant humidity up to 95% at 37 °C, – maintenance-free sensor for CO2 concentration control, – HEPA filter at gas inlet to protect samples from contamination, – the device has temperature control from a minimum of +7 °C above ambient temperature up to 55 °C with a sensitivity of 0,1 °C |

| Model: |

| Thermo Fisher Heracell Vios 160i |

| Responsible Personnel: |

| Zuzana Neščáková <zuzana.nescakova@tnuni.sk> |

| Automatic cell counting EVE |

| Function and use: |

| Device for automatic cell counting, identification and evaluation of cells (live/dead) and assessment of their viability with visual display. |

| Technical specification: |

| The device allows automatic cell counting, identification of cells – live/dead and assessment of their viability, – staining with trypan blue, – cell size adjustment, ranging from a minimum of 6-60 μm, – the possibility to measure in a concentration range of at least 105-106 cells/ml, – the possibility of storing the data on a data carrier |

| Model: |

| NanoEnTek EVE Automatic cell counter |

| Responsible Personnel: |

| Zuzana Neščáková <zuzana.nescakova@tnuni.sk> |

| Refrigerated centrifuge Eppendorf |

| Function and use: |

| Universal laboratory refrigerated bench centrifuge (centrifuge). The centrifuge is designed for processing and separation of samples in different types of tubes. |

| Technical specification: |

| Processing and separation of samples in different types of tubes with a minimum volume range of 1.5/2 ml, 15 ml and 50 ml, – speed range from 200 – 14000 rpm, – a temperature setting with a minimum range of -9 °C to +38 °C, – an installed timer ranging from 1 min to 99 min and autoclavable angular rotors, – angular rotor with a capacity of 24 x 1,5/2 ml tubes, – an angular rotor with a capacity of 6 x 15 ml tubes, – an angular rotor with a capacity of 6 x 50 ml tubes. |

| Model: |

| eppendorf 5804 R |

| Responsible Personnel: |

| Zuzana Neščáková <zuzana.nescakova@tnuni.sk> |

| Biological Safety Cabinet ESCO |

| Function and use: |

| A Biological Safety Cabinet (BSC), also known as a Biosafety Cabinet is mainly used for handling pathogenic biological samples or for applications that require a sterile work zone. A biological safety cabinet creates inflow and downflow of air that provides operator protection. |

| Technical specification: |

| EN 12469: 2000 Biotechnology – Performance criteria for microbiological safety cabinets is the new harmonized European standard for microbiological safety cabinets, published by CEN, the European Committee for Standardization. This standard classifies BSCs into to Class I, Class II, and Class III. |

| Model: |

| Biological Safety Cabinet ESCO |

| Responsible Personnel: |

| Zuzana Neščáková <zuzana.nescakova@tnuni.sk> |

| Laboratory glassware washer Miele – Equipment for washing and disinfection of glassware and instrumentation |

| Function and use: |

| Equipment for washing and disinfection of laboratory instrumentation (flasks, test tubes, slides, petri dishes, pipettes, etc.) to achieve the required cleanliness for high reproducibility of experiments and elimination of contamination of prepared materials |

| Technical specification: |

| Integrated drying unit with HEPA filters at the inlet of the drying air and final rinse with demineralised water, electronic control of operation with the possibility of selecting programs (according to type, volume, shape, contamination of laboratory glassware), their storage in memory and a port for process documentation, integrated vapour condenser and vapour-tight connection of waste to the sewage system, circulation pump with a flow rate of 350 l/minute, integrated water softener with direct connection to the cold or hot (up to 70 °C) pressurised water supply |

| Model: |

| PG 8583 CD ADP/Miele |

| Responsible Personnel: |

| Zuzana Neščáková <zuzana.nescakova@tnuni.sk> |

| Deep freezer box |

| Function and use: |

| Deep freezer box for storage and preservation of biological materials and samples – bacteria, cells, tissues and preservation of chemicals or test components of materials for longer periods of time |

| Technical specification: |

| Volume of 100 litres, allow long-term storage of samples at temperatures ranging from at least -60 °C to -86 °C |

| Model: |

| CryCube F101h/ Eppendorf |

| Responsible Personnel: |

| Zuzana Neščáková <zuzana.nescakova@tnuni.sk> |

| Inverted microscope with fluorescence |

| Function and use: |

| Inverted fluorescence optical microscope allowing measurements in transmitted light in brightfield and phase contrast and optionally in reflected light in epi fluorescence |

| Technical specification: |

| Equipped with a turret head for 4 lenses, 4 long working distance objectives allowing measurements at magnifications, 4x or 5x – 11 mm, 10x – 8.5 mm, 20x – 4,5 mm, 40x – 2.5 mm. – Binocular tube with eyepieces with a minimum magnification of 10x and a field of view width of 22 mm with a dioptric correction of ±5 diopters, – equipped with one port for connecting a digital camera with an optical path ratio of at least 100-0/0-100 |

| Model: |

| Eclipse Ts2R-FL/Nikon |

| Responsible Personnel: |

| Zuzana Neščáková <zuzana.nescakova@tnuni.sk> |

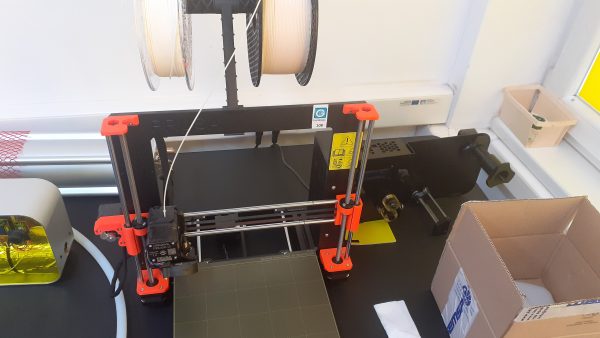

Equipment to produce 3D structures with extrusion-based printing method

Function and use:

The 3D-Bioplotter is a rapid prototyping machine especially designed for the fabrication of scaffolds for biomedical applications. Utilize a wide range of materials from soft hydrogels over polymer melts to hard ceramics.

Technical specification:

Building platform size 200x220x140 mm, building platform temperature control from -10 °C to 80 °C, computer-controlled print head movement with a resolution of ≤ 0,001 mm in the x, y and z directions, device equipped with print heads for printing at low temperatures – in the temperature range from 0 °C to 70 °C, as well as at high temperatures – in the temperature range from 30 °C to 250 °C.

Model:

EnvisionTEC GmbH 3D-Bioplotter® Developer Series

Responsible person:

Fatih Kurtuldu, PhD. fatih.kurtuldu@tnuni.sk

| Laboratory cooled incubator SMART Pol-Eko |

| Function and use: |

A cooled incubator for working with biological material sensitive to external temperature changes can provide a stable temperature between +3 – +70 °C regardless of ambient conditions.

|

| Technical specification: |

| an internal volume of at least 110 litres, – an internal sealed transparent door for visual inspection of samples without alteration of the internal environment,– microprocessor-based temperature control with a minimum temperature range of +3 °C to +70 °C with display, adjustment in increments of 0,1 °C, – forced air circulation |

| Model: |

| POL-EKO Cooled incubator ST 2 C Smart |

| Responsible Personnel: |

| Zuzana Neščáková <zuzana.nescakova@tnuni.sk> |

| Shaking Incubator Labwit |

| Function and use: |

| Benchtop shaking incubators offer a comprehensive range of growth requirements for biological organisms, including time, temperature, and orbital or reciprocal agitation. Provides constant control at a fixed temperature and speed. Or programmed control with a series of “ramps and soaks” segments on a time basis |

| Technical specification: |

| Adjustable shaking motion from 50 – 580 rpm, adjustable shaking radius from 1 – 40 mm, – cooling of the inner chamber, temperature adjustable from 5 °C to 60 °C, – internal chamber volume 69 l, – timer with range from 1 min – 9000 min, – temperature accuracy ± 0,1 °C, – temperature uniformity ± 1 °C at 37 °C , |

| Model: |

| ZWYR-200D Series Shaking Incubator |

| Responsible Personnel: |

| Zuzana Neščáková <zuzana.nescakova@tnuni.sk> |

| Laboratory autoclave sterilizer Tuttnauer – Equipment for decontamination of materials |

| Function and use: |

| Equipment for decontamination (destructive sterilization) of materials resulting from work with cell and microbiological cultures through the action of moist warm air – steam and increased pressure. |

| Technical specification: |

| Vertical top loading autoclave with chamber size 85L. Sterilization temperature range from 105°C to 137°C Optional Disinfection/Isothermal Temperature range from 60°C to 105°C .Optional Independent Recording for cross-checking cycle measurements. Filter replacement notifications based on the number of cycles |

| Model: |

| 3870 elv d-LINE/TUTTNAUER |

| Responsible Personnel: |

| Zuzana Neščáková <zuzana.nescakova@tnuni.sk> |

| Clean water production system type II |

| Function and use: |

| Type II clean water system for the production of an analytically clean water for sensitive experiments. |

| Type II pure water preparation system a device for the production of an analytically pure polar inorganic solvent, – Type II pure water parameters at the outlet: water resistivity 10-15 MΩ.cm at 25 ˚C, carbon content < 30 ppb, micro-organism content < 10 KTJ/ml, – Type II clean water production – 5 l/hr, – UV lamp for destruction of microorganisms in the medium, – electrodeionisation module , no need for anode decalcification or removal of sedimented particles from the anode, no need for resin replacement or maintenance, – a recovery range of 25-46 % depending on the quality of the input medium-with water tank 75L |

| Model: |

| Merck Millipore Elix Essential 5 UV |

| Responsible Personnel: |

| Zuzana Neščáková <zuzana.nescakova@tnuni.sk> |

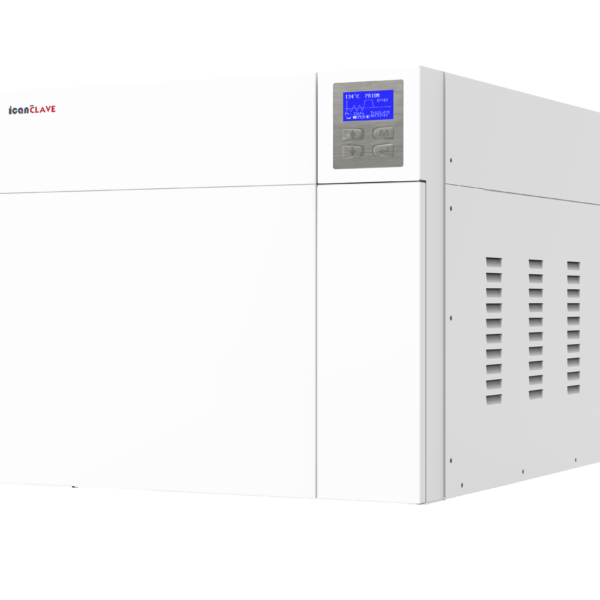

| Steam Sterilizer iCanclave |

| Function and use: |

| Steam sterilizer iCanclave is full automatic table top autoclave with pre-set programs.

Complies with European standard EN13060. In built independent rapid steam generator ensures quick sterilization cycles. Rapid post sterilization vacuum drying. Three cycle options (standard programs), which are preset for the sterilization of liquids, wrapped instruments or unwrapped instruments/plasticware. |

| Technical specification: |

| Each program has a choice of two temperature settings:121 °C and 134 °C. For special applications, requiring variations in cycle parameters, all settings on the BioClave 16 are fully adjustable with a digital program control. |

| Model: |

| STE-B18-C iCanclave |

| Responsible Personnel:

Zuzana Neščáková <zuzana.nescakova@tnuni.sk> |

| Microplate Spectrophotometer EPOCH |

| Function and use:

Epoch microplate spectrophotometer has monochromator-based optics, for a filter-free, wide wavelength range for UV-Vis absorbance measurements. These measurements can be done in many microplate formats and in 2 µL samples, when the available microvolume plate is used. Epoch is controlled by Gen6 Data Analysis Software, with simple programming and powerful data analysis. |

| Technical specification:

Wavelengths from 200 to 999 nm for UV-Vis applications enable fast nucleic acid and protein quantification in microplates. Qualitative and quantitative colorimetric assays . Microvolume detection for small, 2 µL sample volumes for direct DNA, RNA, and protein quantification. Get rapid results for up to 48 samples at a time. |

| Model: |

| Spectrophotometer EPOCH |

| Responsible Personnel: |

| Zuzana Neščáková zuzana.nescakova@tnuni.sk |

|

Flow cytometer Function and use: |

| It is a compact instrument for the analysis of individual cells and microscopic particles in suspension. Benchtop multiparametric flow cytometer with two excitation sources and the ability to detect 4 stains in a single analysis |

| Technical specification: |

| Excitation by at least 2 excitation sources: one with 488 nm ±2 nm excitation and one with 640 nm ±2 nm excitation, – 4 detection channels, – light scattering detectors – FSC and SSC, – a range of measured cell sizes from 0,2 – 60 μmThe easy-to-use CyFlow software provides control of the instrument, data acquisition, analysis and storage. CyFlow Cube 6 offers True Volumetric Absolute Counting (TVAC), which allows the display of particle concentrations for any subsets of cells without the need for reference beads, even if defined by a gate at a later time after the acquisition. |

| Model: |

| CYFloww Cube6 N1/Sysmex Europe GmbH |

| Responsible Personnel: |

| Zuzana Neščáková <zuzana.nescakova@tnuni.sk> |

Sample preparation

| Laboratory fume hood for work with hydrofluoric acid |

| Function and use: |

| Laboratory fume hood is used for extraction of vapors, gases and harmful substances when working with chemicals, toxic substances in experimental work in the laboratory; 2. Ultrasonic cleaner is used for cleaning, dissolving or degassing. |

| Technical specification: |

| Dimension – width mm 1 198 Dimension – depth mm 928 Dimension – height mm 2 498 |

| Model: |

| N – DIG N-1200/900 M2 MERCI |

| Responsible Personnel: |

| Rajesh Dagupati <rajesh.dagupati@tnuni.sk> |

|

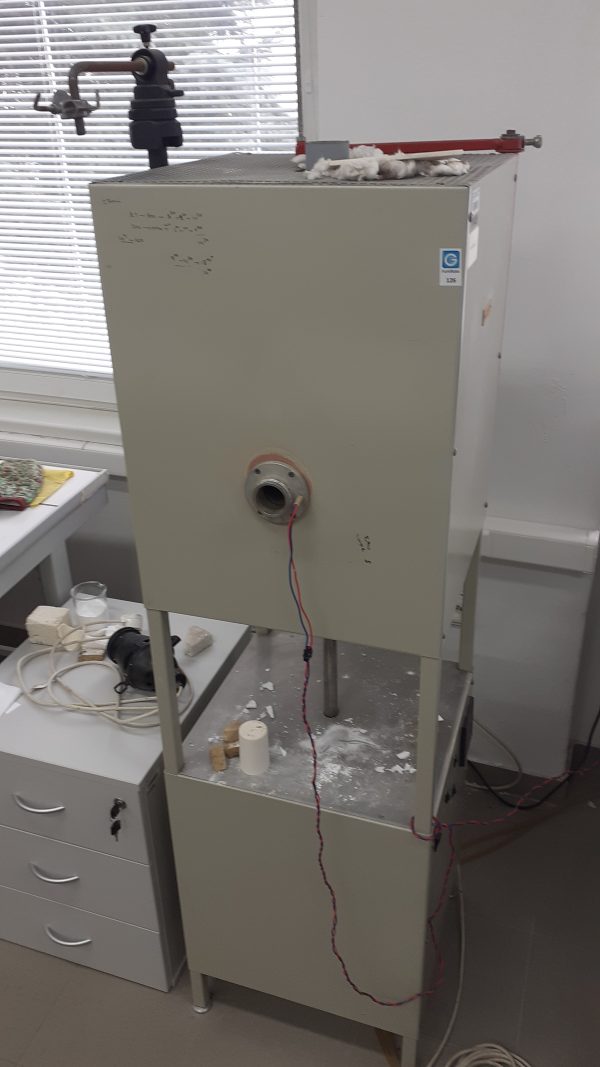

House built equipment for preparation of glass microspheres by flame synthesis |

| Function and use: |

| Equipment for the manufacture of solid, hollow or porous glass or glass ceramic microspheres |

| Technical specification: |

| Maximum flame temperature: 2200°C |

| Model: |

| Responsible Personnel: |

| Jozef Kraxner, jozef.kraxner@tnuni.sk |

| Lab-Cast Model TC-71LC |

| Function and use: |

| Tape Caster has been designed specifically to meet the needs of the small developer and is ideal for lab scale studies. Lab-Cast is simple to use yet sophisticated enough to provide a versatile research and development platform. |

| Technical specification: |

|

| Model: |

| Lab-Cast Model TC-71LC |

| Responsible Personnel: |

| Peter Švančárek, peter.svancarek@tnuni.sk |

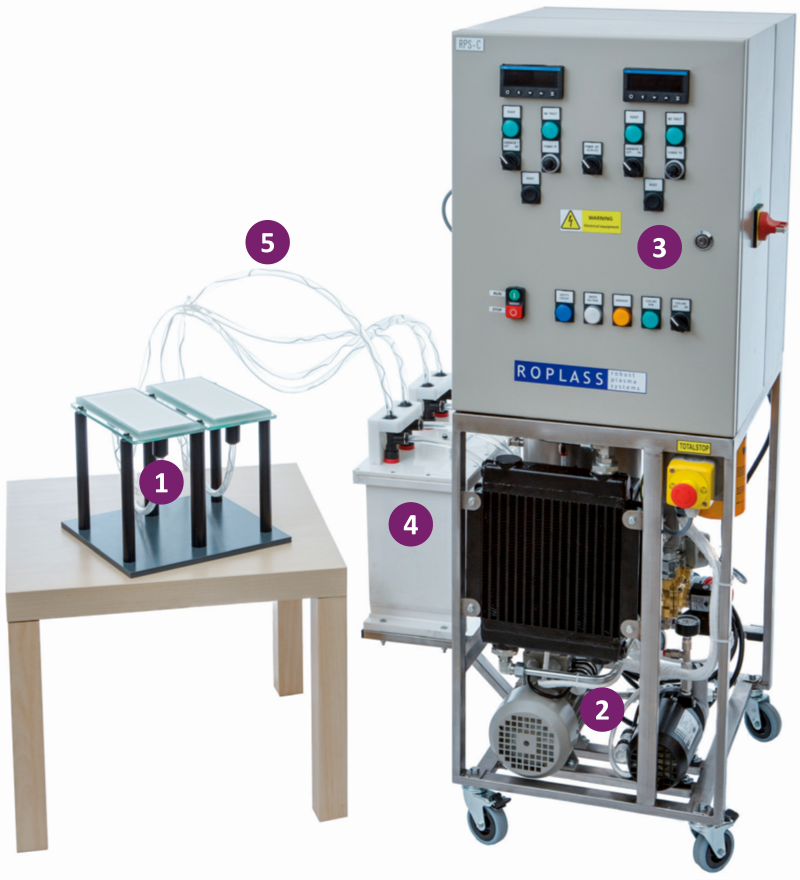

Atmospheric plasma powder processing equipment RPS400 ROPLASS

FUNCTION AND USE:

RPS400 is a unique generator of cold surface plasma in ambient air. The main element is patent-protected diffuse coplanar surface barrier discharge (DCSBD) plasma unit. It enables to generate high-power diffuse plasma, which is efficient for surface treatments of various planar and flexible materials (substrates, scaffolds, films, etc.). Furthermore, RPS400 is suitable for modifying surface characteristics including wetting, electrical charge, OH group concentration of both glass and ceramic powder samples for further application in coatings, 3D printing, biomaterials, etc. Powder samples treated by plasma in an air atmosphere enhance their surface characteristics so that their dispersion and deagglomeration when preparing suspensions is possible without the use of chemical dispersants.

TECHNICAL SPECIFICATIONS:

- DCSBD plasma units

Patent-protected atmospheric pressure source of diffuse cold surface plasma.

- Cooling system

Unique cooling system for keeping the cooling-medium (synthetic oil) ultra-dry and particle-free. The purity of the oil is essential for the proper functionality of the DCSBD plasma unit.

- Power unit

Cutting-edge electrical switch-gear for operating the DCSBD plasma unit.

- HV transformer

Transformer for transforming low-voltage to high-voltage (HV) for supplying DCSBD plasma unit.

- HV wires and oil tubes

High-voltage wires and oil tubes are separated. High-voltage wires are safely insulated and embedded in dielectric cable protectors.

Model:

ROPLASS PLASMA SYSTEM: MODEL RPS2X400-15

Responsible person:

Zulema Vargas, zulema.vargas@tnuni.sk

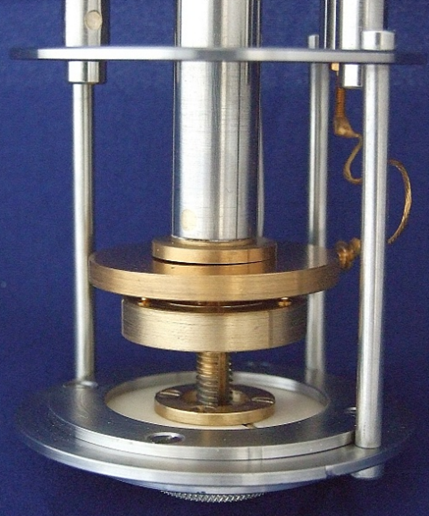

COLD ISOSTATIC PRESS (CIP)

FUNCTION AND USE:

Cold isostatic pressing (CIP) is a convenient tool for producing powder compacts of advanced materials by applying uniform pressure. It is widely accepted as an effective forming method in ceramics and powder metallurgy. Cold isostatic pressing involves compacting powders, usually pellets (max. diameter 15 mm), by enclosing them in an elastomer mould. An elastomer mould is used because it has low resistance to deformation. Liquid pressure is then applied uniformly to the mould to compress it. You are left with a highly compact solid at the end of the process.

TECHNICAL SPECIFICATION:

The maximum pressure is 1000 MPa (1GPa), the inner basket’s diameter is 16 mm, and the compression/decompression speed is adjustable from 20 to 350 MPa/min.

MODEL:

Stansted S-FL-850-12.5 -S.

RESPONSIBLE PERSON:

Milan Parchovianský, milan.parchoviansky@tnuni.sk

DIP COATING EQUIPMENT

FUNCTION AND USE:

Dip coating is a widely used deposition technique for obtaining films, layers, and coatings. The Nadetech ND-DC Dip Coater is an automated unit fabricating thin films and coatings via dip coating. Its design and programmable software permit the control and automation of every deposition parameter with high accuracy and reproducibility. The ND-DC achieves coatings with one or multiple layers through dip coating techniques, such as sol-gel, polymeric layers, self-assembled monolayers, biofilms, and other layers and coatings.

TECHNICAL SPECIFICATION:

– a vertical immersion range of 0-150 mm

– minimum speed 0.01 mm/min.

– maximum speed 150 mm/min.

– programmable functions: immersion and retrieval speeds, vertical displacement, initial substrate position, immersion time and drying time,

– accessories – cabin, multisample holder, humidity & temperature sensor, pH sensor, magnetic stirrer, touchscreen

MODEL:

Nadetech ND-DC Dip Coater 150

RESPONSIBLE PERSON:

Milan Parchovianský <milan.parchoviansky@tnuni.sk>

| Low Speed Saw Buehler IsoMet | ||

| Function and use: | ||

| The precision sectioning saw is designed for cutting various types of materials with minimal deformation. This precision cutting machine is ideal for delicate parts by only using gravity fed force. The low speed sectioning tool is able to cut virtually any material including brittle or ductile metals, composites, cements, laminates, plastics, electronic devices and biomaterials. | ||

| Technical specification: | ||

| Cutting Capacity | 1.50[in}, 38[mm] | |

| Wheel Diameter | 5.00[in], 127[mm] | |

| Cut Action | Gravity Fed Cut | |

| Model: | ||

| IsoMet Low Speed Saw | ||

| Responsible Personnel: | ||

| Mariana Švančárková <mariana.svancarkova@tnuni.sk> | ||

| Semi-Automatic Grinder-Polisher Buehler MiniMet 1000 | |||

| Function and use: | |||

| The MiniMet 1000 Grinder/Polisher is designed for low volume laboratories preparing single specimens. This semi-automatic grinder-polisher comes with suggested programs for a wide variety of materials. The easy-to-use controls allow for selection of speed, pressure, time and soft stop capability. The MiniMet 1000 completely controls the preparation process and assures complete repeatability. | |||

| Technical specification: | |||

| Voltage/Frequency/Phase | 85 – 264 V / 50 – 60Hz / 1 phase | ||

| Shipping Weight | 25 lbs (11 kg) | ||

| Model: | |||

| MiniMet 1000 Semi-Automatic Grinder-Polisher | |||

| Responsible Personnel: | |||

| Mariana Švančárková <mariana.svancarkova@tnuni.sk> | |||

SPIN COATING EQUIPMENT

FUNCTION AND USE:

Spin coating is a procedure used to deposit uniform thin films, layers, and coatings onto flat substrates. Usually, a small amount of coating material in liquid form is applied to the substrate’s centre, either spinning at low speed or not spinning at all. The substrate is then rotated to spread the coating material by centrifugal force. Holmarc’s Spin Coater is a dedicated tabletop system that spin coats small substrates in research laboratories with well-controlled spin process parameters. The high speed and duration range allows the user to achieve the desired thickness or thinness of the film. A vacuum chuck powered by an oil-less vacuum pump holds the substrate at the spinning head.

TECHNICAL SPECIFICATION:

Spinning speed: 60 – 9999 rpm

Substrate diameter: 30 mm to 70 mm

Spin chamber: Nylon

Acceleration: 5 – 2000 rpm/sec

Spinning Speed Accuracy:< 5%

Programmable parameters: Speed, Acceleration, Dwell time and No. of steps

Maximum no of steps: 9

Program memory: 9 programs (non–volatile)

Dimension: 400mm D x 275mm W x 331mm H

MODEL:

Holmarc HO-TH-05.

RESPONSIBLE PERSON:

Milan Parchovianský <milan.parchoviansky@tnuni.sk>

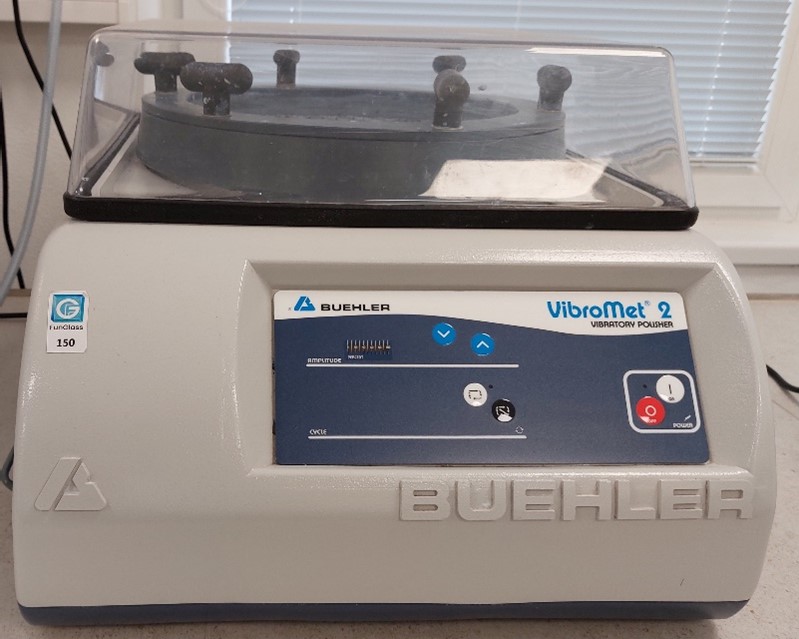

| Vibratory Polisher Buehler VibroMet 2 | ||

| Function and use: | ||

| The vibratory polisher is a machine designed to prepare high quality polished surfaces on a wide variety of materials suitable for atomic force microscopy (AFM) or electron-backscatter difraction (EBSD) applications. After mechanical specimen preparation, the VibroMet Vibratory Polisher removes any minor deformations remaining. This reveals a stress-free surface without need for the hazardous electrolytes required by electro-polishers. | ||

| Technical specification: | ||

| Voltage/Frequency/Phase | 220 V / 50 Hz / 1 phase | |

| Wattage | 30 W | |

| Shipping Weight | 175 lbs (80 kg) | |

| Model: | ||

| VibroMet 2 Vibratory Polisher | ||

| Responsible Personnel: | ||

| Mariana Švančárková mariana.svancarkova@tnuni.sk | ||

| Laboratory Planetary Mill Fritsch Pulverisette 5 | ||

| Function and use: | ||

| The laboratory planetary mill can be used universally for high-speed wet and dry grinding of inorganic and organic samples for analysis, quality control or material testing. In the case of synthesis, the planetary mill is used to mix and homogenise dry samples, emulsions or pastes. The material to be ground is crushed and torn apart by grinding balls in 2 or 4 grinding bowls. The centrifugal forces created by the rotation of the grinding bowls around their own axis and the rotating supporting disc are applied to the grinding bowl charge of material and grinding balls. | ||

| Technical specification: | ||

| Working principle | impact force | |

| Optimal for material type | hard, medium-hard, soft, brittle, tough, moist | |

| Number of working stations | 4 | |

| Grinding bowl sizes | 80, 250, 500 ml | |

| Grinding ball diameter | 0.1 – 40 mm | |

| Max. feed size (depends on material) | 10 mm | |

| Sample quantity | 10-900 ml | |

| Final fineness (depends on material) | < 1 µm | |

| Rotational speed of main disk | 50 – 400 rpm | |

| Weight | 120 kg | |

| Model: | ||

| Laboratory Planetary Mill Pulverisette 5 | ||

| Responsible Personnel: | ||

| Anna Prnová <anna.prnova@tnuni.sk> | ||

Vibratory Micro Mill Fritsch Pulverisette 0

| Function and use: | |

| The mill is used for the fine comminution of medium-hard, brittle, moist or temperature-sensitive samples – dry or in suspension. It can be used for homogenising emulsions or pastes. | |

| Technical specification: | |

| Working principle | Impact force |

| Optimal for material type | medium-hard, brittle, temperature-sensitive, moist |

| Grinding tools | mortar and grinding ball |

| Max. feed size (depends on material) | 5 mm |

| Sample quantity | 1-10 ml |

| Final fineness (depends on material) | 10 µm |

| Grinding bowl oscillations per minute | 3,000 – 3,600 at 1-3 mm amplitude |

| Weight | 21 kg |

| Model: | |

| Vibratory Micro Mill Pulverisette 0 | |

| Responsible Personnel: | |

| Anna Prnová <anna.prnova@tnuni.sk> | |

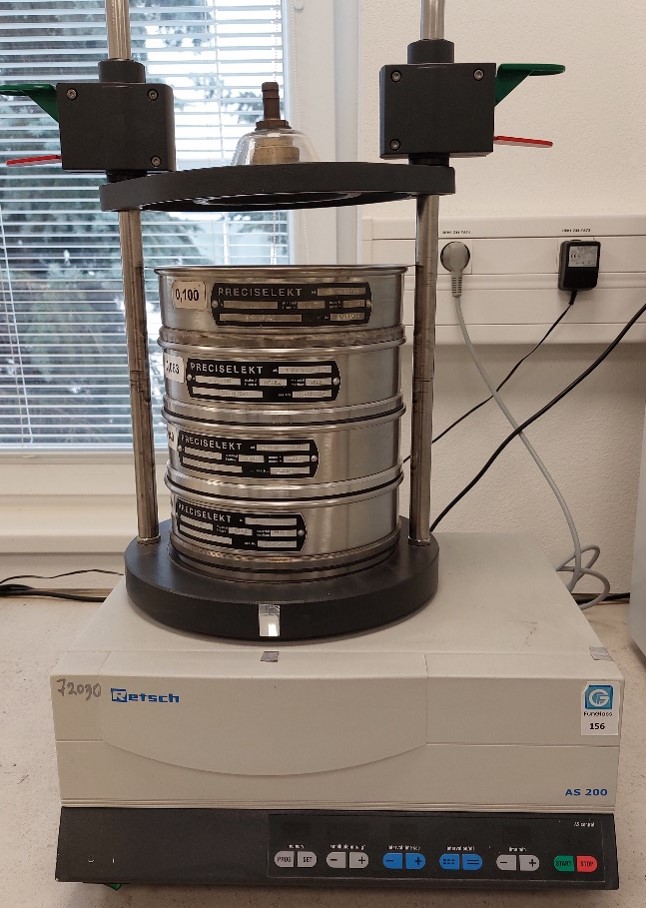

Vibratory Sieve Shaker Retsch AS 200 Control

| Function and use: | ||

| The vibratory sieve shaker is suitable for both, dry and wet sieving of free-flowing, disperse materials in the grain size range from 20 µm to 25 mm. The particle size distribution of soils, building materials, chemicals, fertilizers, fillers, grains, coffee, plastics, flour, metal powders, minerals, nuts, seeds, sand, washing powder, cement clinker and many other substances can be easily and quickly analysed. | ||

| Technical specification: | ||

| Applications | separation, fractioning, particle size determination | |

| Feed material | powders, bulk materials, suspensions | |

| Measuring range | 20 µm – 25 mm | |

| Max. batch / feed capacity | 3 kg | |

| Max. mass of sieve stack | 6 kg | |

| Amplitude | digital, 0.2 – 3 mm | |

| Sieve acceleration | 1.0 – 15.1 g | |

| Time display | digital, 1 – 99 min | |

| Interval operation | 1 – 99 s | |

| Max. height of sieve stack | 620 mm | |

| Net Weight | 35 kg | |

| Model: | ||

| Vibratory Sieve Shaker AS 200 Control | ||

| Responsible Personnel: | ||

| Anna Prnová <anna.prnova@tnuni.sk> | ||

Grinder-Polisher Buehler EcoMet 300 Pro/AutoMet 300 with automatic polishing suspension dispenser

Function and use:

The EcoMet 300 Pro /AutoMet 300 is a semi-automatic system, allowing simple adjusting of grinding/polishing process. Both the EcoMet 300 Pro grinder-polisher and AutoMet 300 power head feature adjustable rate of rotation. In addition, the AutoMet 300 power head has the adjustable direction of rotation. The samples are individually pressed toward the grinding/polishing wheel by AutoMet 300 power head using pneumatic pistons. The level of pressure is programmed by user.

Technical specifications

Motor Power of the EcoMet 300 Pro: 2 Hp (1500 W)

Ecomet Pro touch screen with GUI- programmable

Platen Wheel Speed: 50-400 rpm, in 10 rpm increments

Water Supply Hose 4″ (6mm) OD tube

Water Supply Pressure 40-100 psi (2.8-6.9 bar)

Water Return Hose 1″ (25mm) ID tube

AutoMet® Power Head Motor Power 560 W

Rotation Direction Complementary or contra (Clockwise or counterclockwise)

Speed 60-150 rpm, in 10 rpm increments

Central Specimen Force 10-120 lbs (40-535 N)

Single Specimen Force 1-20 lbs (5-90 N)

Air Supply Hose 0.23″ (6mm) OD tube

Air Supply Pressure 35 psi (2.4 bar)

Polishing suspension dispensing system: power consumption up to 264W

Model:

Buehler EcoMet 300 Pro/AutoMet 300 with automatic polishing suspension dispenser

Responsible person:

Peter Švančárek peter.svancarek@tnuni.sk

Automatic & Manual Abrasive Cutter AbrasiMatic 300

Function and use:

The AbrasiMatic 300 is a benchtop dual abrasive cutting machine featuring manual cutting action in 3 directions or automated cutting in 1 direction. This abrasive cutter enables variety in sample preparation to best fit each sample process with both manual and automatic abrasive cutting capabilities. It is engineered with innovative capabilities to be used in both production support and laboratory environments.

Technical specification:

Power Consumption: 4.0kW

Maximum Current: 15.7amps @ 220/230VAC; 7.9amps @ 460VAC; 9.1amps @ 380VAC

Motor Power: 5Hp [3.7kW]

Lighting: Two LED Goosenecks

Travel movement: Z-Axis: 5.75in [150mm]; Y-Axis: 10.25in [260mm]; X-Axis: 2.75in [70mm]

Auto Y-Axis Feed Rate: 0.7-5in/min [0.3-2mm/sec]

Abrasive Wheel Diameter: maximum 12in [305mm]

Arbor: 1.25in [32mm]

Maximum Cut Diameter : 4.375in [110mm]

Water cooled; Recirculation Tank Capacity: 22gal [83ℓ]

Model:

Buehler AbrasiMatic® 300 Abrasive Cutter

Responsible Personnel:

Peter Švančárek <peter.švančárek@tnuni.sk>

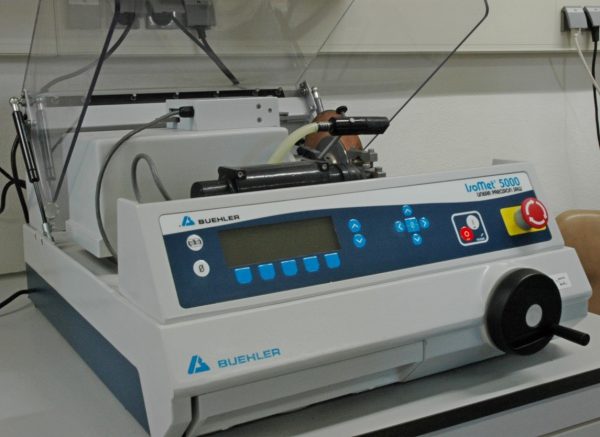

Linear Precision Saw Buehler IsoMet 5000

Function and use:

The IsoMet 5000 is an easy-to-use automatic linear saw that includes the SMARTCUT system to automatically adjust the feed rate to provide consistent, quality cuts and to prevent specimen and machine damage. A 2mm Specimen Positioning System allows for precise applications and enables the cutting of delicate specimens without deformation. The IsoMet 5000 also provides automatic serial sectioning for multiple cuts to a desired thickness and has method programmability.

Technical specification:

Electrical: 85 – 264 V, 50/60 Hz, 1 Phase

Motor: 1 ¼ HP (795 W) 200 – 5000 rpm

Blade Speed: 200 – 5000 rpm

Feed Rate: 0.05 – 0.75 in/min [1.27 – 19 mm/min]

Cutting Distance: 0.01 – 8.00 in [0.26 – 203 mm]

Sample Thickness: 0.005 – 0.985 in [0.12 – 25 mm]

Specimen Quantity: 1 – 100

Blade Thickness: 0 – 0.035 in [0 – 0.899 mm] Water cooled; Recirculation Tank Capacity: 7gal [26.5ℓ]

Model:

IsoMet 5000 Linear Precision Saw

Responsible Personnel:

Peter Švančárek <peter.svancarek@tnuni.sk>

Carbon Sputter-Coater JEOL JEC-530

Function and use:

Used for sputtering of fine electrically conductive layer of graphite(carbon) on samples for electron microscopy.

The equipment is complementary to the electron microscope and provides the necessary preparation of non-metallic, non-conductive samples but also conductive samples which form oxide layers on surface.

Technical specification:

Carbon sputtering using high temperature evaporation of carbon.

Automatic or manual sputtering

Allows adjustment of sputtering voltage and time.

Model:

JEOL JEC-530

Responsible person:

Peter Švančárek, peter.svancarek@tnuni.sk

AUTO Sputter-Coater JEOL JFC-1300

Function and use:

Used for sputtering of fine electrically conductive layer on samples for electron microscopy.

Deposited metals can be Au, Pt or Au/Pd.

The equipment is complementary to the electron microscope and provides the necessary preparation of non-metallic, non-conductive samples but also conductive samples which form oxide layers on surface.

Technical specification:

RF magnetron sputtering

Deposited layers: gold, silver, platinum, gold/palladium alloys.

Automatic or manual sputtering

Allows adjustment of sputtering current and time.

Model:

JEOL JFC-1300

Responsible person:

Peter Švančárek, peter.svancarek@tnuni.sk

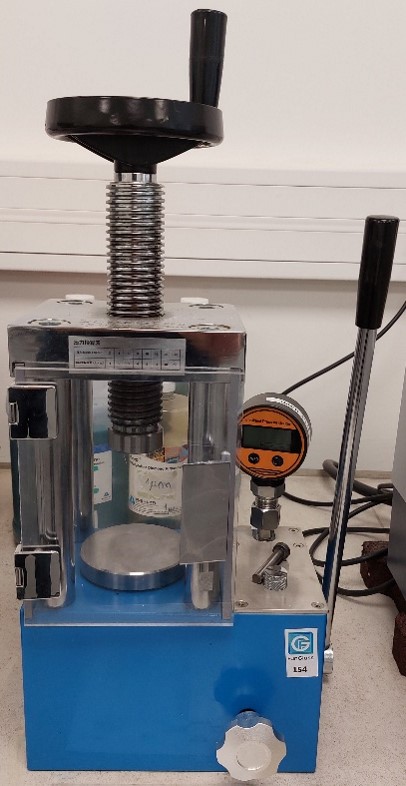

Manual 15t Hydraulic Press

Function and use:

Used for press-forming powders into pellets before sintering.

Technical specifications

2MPa -> 1ton

Max. allowed pressure 30MPa on gauge!

Mechanically operated

Protective shield

Responsible person:

Peter Švančárek peter.svancarek@tnuni.sk

Hot Mounting Press Buehler SimpliMet 1000

Function and use:

Easy-to-use automatic mounting press. It is used for embedding of specimen into plastic cylinders using pressure and elevated temperature for a good edge retention. Increases productivity and sample consistency. Excellent for embedding of samples before polishing. Recommended for samples measured by SEM.

Technical specifications

25mm die

Duplex Mold Capacity- possibility to mount up to two specimens in a Single Cycle

LCD Display with backlit lighting

SimpliMet 1000 control touch-pad

Electro-Hydraulic Operation

Tap water cooled

Universal Power Supply

Resettable, Built-in Circuit Protection

Model:

Buehler SimpliMet 1000

Responsible person:

Peter Švančárek peter.svancarek@tnuni.sk

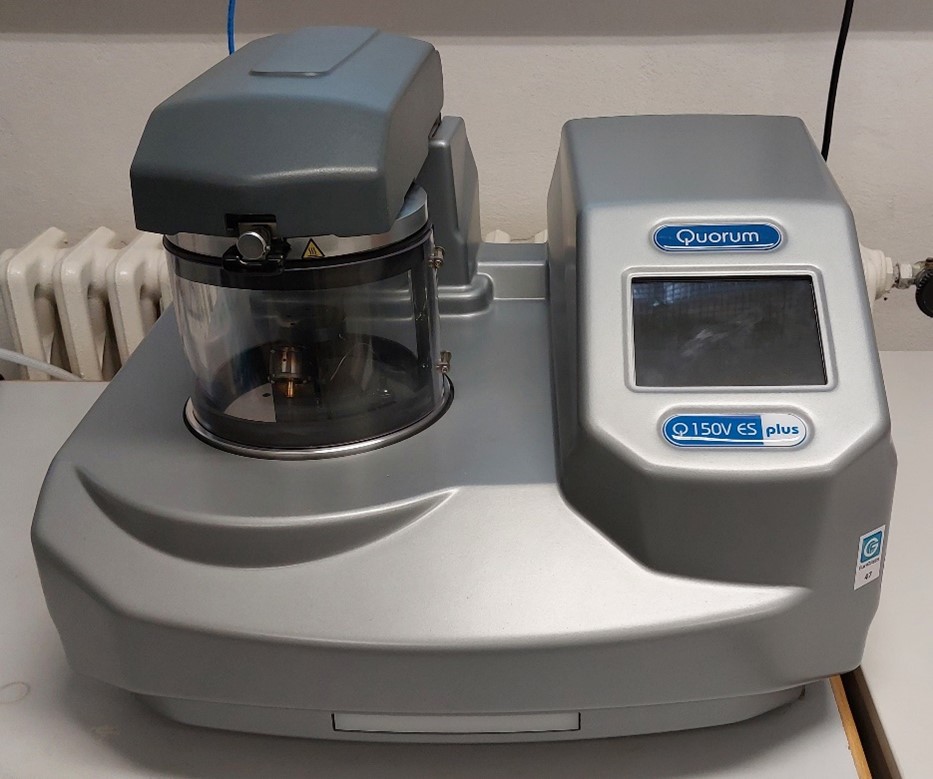

Sputter-coater Quorum Q150V ES plus

Function and use:

Used for sputtering of fine electrically conductive layer of metal or graphite(carbon) on samples for electron microscopy.

The equipment is complementary to the electron microscope and provides the necessary preparation of non-metallic, non-conductive samples but also conductive samples which form oxide layers on surface.

Technical specification:

Sample size up to 50mm

Automatic coating using GUI, backlit display with touchscreen. Programmable, programs can be stored

Coating/sputtering of metals using RF magnetron for sputtering of metals: Au, Pd, Pt, Ag, Ir and others

Carbon sputtering using high temperature evaporation of carbon.

High vacuum for fine layers of coat. Two step vacuum pumping- 1st step oil slat pump and 2nd step vacuum turbopump.

Adjustable distance of specimens from generator of coating.

Model:

Quorum Q150V ES plus

Responsible person:

Peter Švančárek peter.svancarek@tnuni.sk

Grinder-Polisher Buehler EcoMet 300 /AutoMet 300

Function and use:

The EcoMet 300 /AutoMet 300 is a semi-automatic system, allowing simple adjusting of grinding/polishing process. Both the EcoMet 300 grinder-polisher and AutoMet 300 power head feature adjustable rate of rotation. In addition, the AutoMet 300 power head has the adjustable direction of rotation. The samples are individually pressed toward the grinding/polishing wheel by AutoMet 300 power head using pneumatic pistons. The level of pressure is programmed by user.

Technical specifications

Motor Power of the EcoMet 300: 2 Hp (1500 W)

Membrane button control pannel

Platen Wheel Speed: 50-400 rpm, in 10 rpm increments

Water Supply Hose 4″ (6mm) OD tube

Water Supply Pressure 40-100 psi (2.8-6.9 bar)

Water Return Hose 1″ (25mm) ID tube

AutoMet® Power Head Motor Power 560 W

Rotation Direction Complementary or contra (Clockwise or counterclockwise)

Speed 60-150 rpm, in 10 rpm increments

Central Specimen Force 10-120 lbs (40-535 N)

Single Specimen Force 1-20 lbs (5-90 N)

Air Supply Hose 0.23″ (6mm) OD tube

Air Supply Pressure 35 psi (2.4 bar)

Model:

Buehler EcoMet 300/AutoMet 300

Responsible person:

Peter Švančárek peter.svancarek@tnuni.sk

Grinder-Polisher Struers TegraPol-35/TegraForce-5

Function and use:

The Struers TegraPol-35/TegraForce-5 is a semi-automatic system, allowing simple adjusting of grinding/polishing process. Both the TegraPol-35 grinder-polisher and TegraForce-5 power head feature adjustable rate of rotation. In addition, the TegraForce-5 power head has the adjustable direction of rotation. The samples are individually pressed toward the grinding/polishing wheel by TegraForce-5 power head using pneumatic pistons. The level of pressure is programmed by user.

Technical specifications

Struers TegraPol-35

Power Requirements: 200-240VAC 10A 2000W

Platen Diameter: 300mm

Speed Range: 40-600RPM

Motor Power: 750W

Struers TegraForce-5

Speed Range: 50-150RPM

Rotation: Clockwise and Anticlockwise

Motor Power: 115W

Torque: 9Nm

Model:

Struers TegraPol-35/TegraForce-5

Responsible person:

Peter Švančárek peter.svancarek@tnuni.sk

Heat treatment and glass melting facilities

| Tube furnace for work in vacuum/controlled atmosphere up to 1800°C | ||||||

| Function and use: | ||||||

| This tube furnace has a max. working temperature up to 1800 ºC. It is widely used in material & chemical research labs to sinter all types of new material samples under vacuum and other gas conditions. | ||||||

| Technical specification: | ||||||

|

||||||

| Model: | ||||||

| Clasic 0118T | ||||||

| Responsible Personnel: | ||||||

| Róbert Klement <robert.klement@tnuni.sk> |

HOT PRESS

FUNCTION AND USE:

The hot press enables the sintering and production of small samples (d=12 mm, 20 mm), especially from powder materials under high temperatures and pressure. The equipment has graphite heating elements. The maximum operating temperature is up to 1800 °C and pressures up to 30 MPa in inert atmospheres (Ar, N) or under vacuum.

TECHNICAL SPECIFICATION:

- External dimensions: 600x800x1000 mm

- Internal dimensions: ø 40 x 50 mm

- Maximum temperature: 1800 °C

- Maximum pressure: 30 MPa (300 bar)

- Heating elements: graphite heating elements

- Heating speed: max. 30°C/min

- Machine power: 12 000 W

- Voltage: 3 x 230/400V + N + PE

- Graphite moulds for powders: diameter 12 and 20 mm

MODEL:

Clasic 0220 ZL

RESPONSIBLE PERSON:

Milan Parchovianský milan.parchoviansky@tnuni.sk

| Vertical tube observation furnace Clasic with CCD camera 4912-5100/0000Observation furnace, Clasic |

| Function and use: |

|

Observation of the processes of glass melting in a special quartz cuvette (glass melting, blackening, foam formation) |

| Technical specification: |

| The device is equipped with a programmable temperature controller up to 1650°C The image is captured by a Pixelink digital camera using image analysis software |

| Model: |

| 4912-5100/0000Observation furnace, Clasic |

| Responsible Personnel: |

| Jozef Kraxner<jozef.kraxner@tnuni.sk> |

| High-temperature elevator furnace |

| Function and use: |

| The base of the furnace is a light steel construction, which all other component parts are connected to. Front side panels and a furnace door are made from stainless steel with a mat ground surface. Fully stainless furnaces can be designed according to customers’ wishes. The pantographic hinge of the door negates turning of the hot door side towards an operator. The model 3014, 5014 and 7014 are equipped with the support 850 mm high. |

| Technical specification: |

| Tmax | Inside w-h-d | Outside w-h-d | Chamber | Voltage | Power | Weight |

| [°C] | [mm] | [mm] | [litre] | [V] | [kW] | [kg] |

| 1300 | 200-160-300 | 470-400-570 | 9,6 | 230 | 7 | 80 |

| Model: |

| Clasic 0718E |

| Responsible Personnel: |

| Jozef Kraxner <jozef.kraxner@tnuni.sk> |

Muffle furnaces

Function and use:

Muffle furnaces are suitable for laboratory testing in which exact temperature distribution, controlled increase and decrease of temperature, and controlled cooling are important, and where it is also desirable that the heating elements are not in the interior space with the samples. These include heating of material for heat treatment of metals, various sintering tests, calcination, determination of the softening or sintering point of materials, burning of samples, firing of enamels, etc. The stainless steel casing ensures a long service life of the furnace, the heating spirals are housed in quartz glass tubes – the spirals are thus partially protected against attack by aggressive substances that can be released from the charge. The programmable controller and the main switch are located on the front of the furnace.

Technical specification:

| Typ | Tmax [°C] | Volume [l] | Ext. Dimensions

(w×h×d) [mm] |

Int.dimensions

(w×h×d)[mm] |

Power input [kW] | Weight [kg] | Voltage [V] |

| LE 05/11 | 1100 | 5 | 470×330×455 | 170×130×230 | 1,8 | 20 | 230 |

| LE 09/11 | 1100 | 9,4 | 490×370×515 | 190×170×290 | 2,3 | 24 | 230 |

Recommended temperature – 700 – 1050 °C

2 muffle furnaces – type LE 05/11

2 muffle furnaces – type LE09/11

Model:

LE 05/11 and LE 09/11 Ht40P, LAC s.r.o

Responsible Personnel:

Milan Parchovianský <milan.parchoviansky@tnuni.sk>

| Tube furnace up to 1200 °C |

| Function and use: |

These compact tube furnace with integrated control systems can be used universally for many processes. Equipped with a standard working tube of C 530 ceramic and two fiber plugs. The tube furnace is also used for pyrolysis of organosilicon precursors in an inert atmosphere at temperatures up to 1200 °C with a programmable temperature controller, it is also used for oxidation and corrosion tests in atmosphere of synthetic air and in water vapour up to 1200 °C.

Technical specification:

Single-zoned design

Dual shell housing made of textured stainless steel sheets with additional fan cooling for low surface temperature

Maximum temperature: 1200 °C

Furnace inner diameter: 70 mm

Heating section length: 500 mm

Total length: 600 mm

The furnace is also equipped with an additional ceramic tube with plugs on both sides, tube length – 800 mm, tube diameter – external – 60 mm, internal – 50 mm

Length of homogeneous temperature field: min. 25% of the total length of the heated section

Control: programmable controller CLARE 4

Control accuracy: ± 1°C

Thermocouple: Pt/PtRh10

Furnace power: 1,8 kW

Voltage, current: 230 V, 8 A

Model: Clasic 0213T, Clasic

| Responsible Personnel: |

| Milan Parchovianský <milan.parchoviansky@tnuni.sk> |

| Chamber furnace for sintering of ceramics up to 1800°C |

| Function and use: |

| Clean chamber furnace for sintering of transparent ceramic after de-binding process, refractory material: alumina |

| Technical specification: |

| maximum temperature up to 1800°C |

| Model: |

| Clasic 1018 S |

| Responsible Personnel: |

| Monika Michálková monika.michalkova@tnuni.sk |

Pressure Autoclave

Function and use:

This high-pressure reactor system is designed for reactions and various applications under pressure, such as hydrothermal reactions, materials testing, thermal pressure hydrolysis, and corrosion testing. It is equipped with a high-torque magnetic drive for efficient mixing and stirring during the process media. The Hastelloy® reactor ensures high resistance against acids.

Technical specification:

Reactor volume: 50ml

Max. pressure: 350 bar

Temperature range: -20 °C to +350 °C

Model:

Büchi Glass Uster / Limbo li

Responsible Person:

Aleksandra Nowicka<aleksandra.nowicka@tnuni.sk>

Climatic Chamber

Function and use:

Climatic chamber is designed for simulating various temperature and humidity environment for high and low temperature and humidity test, temperature cycling, dump heat, dew test and reliability on biological items, industrial products, materials electronic devices and components.

Technical specification:

Temperature range: -40°C – 180°C

Humidity range: 10% – 95%

Internal dimensions: W: 548mm x D: 447mm x H: 447mm

Model:

Angelantoni Discovery DY110

Responsible Person:

Aleksandra Nowicka <aleksandra.nowicka@tnuni.sk>

| High Temperature Laboratory Oven |

| Function and use: |

| Laboratory drying oven designed for applications where accurate and reproducible conditions need to be simulated and designed for long term laboratory testing. With the adjustable temperature and temperature control. |

| Technical specification: |

| Max. temperature: 350°C Min. internal volume: 50 l Max. internal volume: 100 l |

| Model: |

| GHIBLI GH60 |

| Responsible Personnel: |

| Aleksandra Nowicka<aleksandra.nowicka@tnuni.sk> |

Melting furnace with controlled atmosphere

Function and use:

The vacuum furnace is suitable for the preparation of glass with the possibility of mixing the wort, and it is also suitable for firing various materials in the selected inert atmosphere.

Technical specification:

Air-cooled furnace vacuum vessel made of 5 mm thick austenitic chrome-nickel steel and TIG-welded under argon. The lower and upper lids are attached to the furnace shell with gasketed flanges. The internal thermal insulation is made of fibrous corundum with a thickness of 100 mm, resistant to temperatures of 1850°C. Heating is provided by 8 high-temperature elements.

Vacuum vessel made of stainless austenitic steel

– the dimensions of the fusion chamber: inner diameter 180 mm, height 190 mm,

– continuous operating temperature 1600 °C,

– furnace equipped with a programmable control system that allows programming of at least 60 programs containing 40 instructions

Model:

CLASIC CZ, s.r. Laboratory furnace with the possibility of controlling the atmosphere

Responsible Person:

Mária Chromčíková <maria.chromcikova@tnuni.sk>

Physical properties of solids/melts

| Particle Size Analyser and Zeta Potentiometer |

| Function and use: |

| Many processes and products involve disper- sions where optimal results depend on particle size. The technology to produce these dispersions, to en- sure that they perform according to specifications, and to solve problems which may arise in production or use requires knowledge of the particle size |

| Technical specification: |

| Particle sizing from <1 nm to 6 μm

Accomodates wide concentration |

| Model: |

| Brookhaven 90Plus BI-Zeta |

| Responsible Personnel: |

| Ali Talimian<ali.talimian@tnuni.sk> |

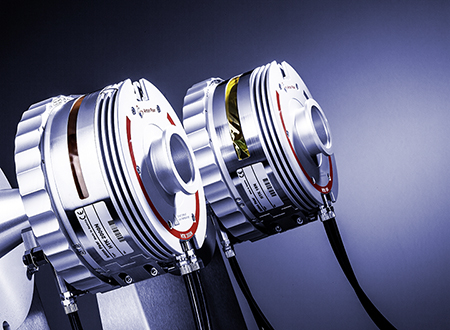

High temperature rotation viscometer

Function and use:

The high temperature viscometers VIS 403 and VIS 403HF measure the dynamic viscosity of materials with Newtonian behavior such as glasses, slags or mold powder. The instrument operates by measuring the shear stress and shear rate of a rotating bob immersed in a fluid filled cup under controlled temperature.

Technical specification:

Viscosity η: 10 – 107 dPA s

Temperature Range: RT to 1500°C or 100°C to 1700°C

Temperature Resolution: 0.1°C

Sample volume: 13.8 or 9.2 cm-3

Rotor diameter: 9 or 19 mm

Measuring system material: Pt/Rh 30%

Torque Range: 0.1 to 50 mN m

Torque Accuracy: ±1%

Angular Velocity: max. 80 rad/s

Angular Velocity Resolution: 10-4 rad

Atmosphere: air, inert gas

Model:

BAHR Vis 403

Responsible Person:

Jozef Kraxner <jozef.kraxner@tnuni.sk>

Gradient furnace, Clasic 4015 SP

Function and use:

The Gradient Heating Furnace (GHF) is a furnace that contains various heating blocks. Their positions and temperatures can be independently controlled, and various temperature profiles can be realized. We typically use it to perform controlled heat treatment at multiple temperatures at once on a variety of glasses and phosphor/ceramic materials.

Technical specification:

External dimensions: 1500x300x550 mm

International dimensions: 333 X 600 mm

Maximum temperature: 1550 °C

Operating temperature: 1500 °C

Heating elements: Wire PtRg20$ 1mm, length 10,000 mm

Insulating lining: Ultraboard 1750

Regulating thermocouple: PtRh6-PtRg30-type B

Measuring thermocouple: Pt-PtRh10-type S

Temperature regulator: CLARE 4.0

Temperature measuring device: Ht 60 M

Heating speed: min. 20°C/min

Device power: 2000 W

Voltage: 230 V +N+PE

Working temperature: 0-40 °C

Humidity: 10- 90 %

Model:

Clasic 4015 SP

Responsible Person:

Branislav Hruška <branislav.hruska@tnuni.sk>

House-built equipment for measurement of physical properties of glass melts

Function and use:

Apparatus KOM is the basic device used to determine melt density and electrical conductivity. KOM includes programmable temperature regulation up to 1550°C. The methodology for determining the density of glass is suitable for quick checks of the correctness of the production process.

Technical specification:

Specific electrical conductivity is measured by an automatic RLC bridge BM595 (Tesla Brno) using 50 mV AC with a frequency of 20 kHz. Measuring electrodes of circular shape made of Pt-Rh.

Model:

House-built equipment for measurement of physical properties of glass melts

Responsible Person:

Branislav Hruška<branislav.hruska@tnuni.sk>

Hot stage microscope, Zeiss

Function and use:

The basic device for determination of surface tension is a heating microscope. The profile of a drop is scanned by a digital camera uEye and analysed by software QuickPHOTO Industrial. Sufficient and adequate glass surface tension data and its temperature dependence is important for the optimal adjustment of the production process.

Technical specification:

The apparatus is equipped with a programmable temperature controller up to 1450 °C.

Model:

Hot stage microscope, Zeiss

Responsible Person:

Branislav Hruška <branislav.hruska@tnuni.sk>

Function and Use

(a) ModuLab XM ECS

The Electrochemical system (ECS) is a highly versatile electrochemical test system that measures the characteristics of a wide range of electrochemical systems including organic/inorganic, specialized corrosion, electroplating and energy cells.

For testing energy devices the system is able to conveniently measure time domain (DC) and impedance characteristics of complete cells, or of individual cells in a high voltage stack, or individual anodes and cathodes within cells using its integrated auxiliary channel measurement capability.

Sample preparation: Electrochemical cells; assembled with three electrode system; Reference electrode; Ag/AgCl, Counter electrode; Pt electrode; Working electrode: Samples coated on steel substrate or glass slides).

(b) ModuLab XM MTS

The Materials Test System (MTS) test combined electrical, thermal, and mechanical properties of dielectrics, insulators and electronic materials. These systems include specialized accessories: High Voltage Amplifiers, Cryostats, Furnaces, and Sample Holders for liquids, powders, and solid materials.

Sample preparation: Two platinum electrodes (5mm/10mm)

Technical specifications

EchemLab XM includes the following reference grade system components:

- Potentiostat / Galvanostat (8V, 300 mA, 1 MHz bandwidth)

- Potentiostat auxiliary channels that can be used for anode/cathode and stack testing

- Frequency Response Analyzer (1 MHz bandwidth)

- EchemLab can also include a 100 V / 100 mA amplifier for high voltage applications. This variant also includes a set of high voltage auxiliary channels for testing cells in a stack at up to 100V

- Optional external power boosters for testing high power cells

Model:

AMETEK; Solartron Analytical ModuLab XM; ECS&MTS System

Responsible Person:

Akansha Akansha<akansha.akansha@tnuni.sk>

| Micro Hardness Tester, WIKI 200 |

| Function and use: |

| The Vickers hardness tester Wiki 200 JS is a fully automatic and motorized hardness testing machine with test loads from 0,001 to 100 kgf. It is suitable for CHD (Case Hardness Depth) tests on multiple samples. Wiki 200 JS is conform to ASTM and ISO hardness testing standard. |

| Technical specification: |

| Model: |

| WIKI 200 |

| Responsible Personnel: |

| Peter Švančárek peter.svancarek@tnuni.sk |

| Equipment for determination of residual stresses in glass – STRAINOPTICS POLARIMETER SYSTEM – ANALYZER A-100 |

| Function and use: |

| Standard Field Polarimeter – General-purpose desktop system, with a 200 x 200 mm viewing area. Includes a circular/plane polarized illuminator and analyzer. Precision measurement of retardation, birefringence, orientation, stress or strain can be achieved in accordance with widely accepted test methods. |

| Technical specification: |

| Model: |

| STRAINOPTICS POLARIMETER SYSTEM – ANALYZER A-100 |

| Responsible Personnel: |

| Branislav Hruška branislav.hruska@tnuni.sk |

Universal test equipment for characterising the mechanical properties of materials

Function and use:

Equipment for testing the mechanical properties of prepared materials at laboratory and elevated temperatures, in particular flexural strength, compressive strength, high temperature strength, resistance to high temperature deformation (creep).

Technical specification:

Measurements with loads up to 100 kN and with servo-electric actuator with a movement speed from 1µm/h to 100mm/min, and load cells allowing accurate measurements of force between ±0.2 N to ±100 kN in compression and tension. The testing fixtures allow measurements in tensile, compression, bending, fibers strength, and fracture toughness according to ASTM and European norms. The device is equipped with high-temperature furnace ( up to 1500°C).

Model:

INSTRON 8862 ±100 kN Dynamic Testing System

Responsible Person:

Ali Talimian, PhD. ali.talimian@tnuni.sk

| Powder deagglomeration plant |

| Function and use: |

| Equipment for deagglomeration of high purity glass and ceramic powders for coating and 3D printing applications as well as for the preparation of polycrystalline transparent materials with luminescent properties. The final product must be an absolutely homogeneous mixture, free of agglomerates or grains which could act as a source of structural defects in the resulting product and thus degrade its properties. |

| Technical specification: |

| Working pressure 200 MPa, minimum nozzle diameter 100 μm, ability to operate in cyclic mode with a capacity of 110 ml/min, ability to process samples even in minimum quantities as small as 3 ml, ability to homogenize/deagglomerate powders, emulsions, dispersions, suspensions, the ability to thermally treat” the sample in the homogenisation/deagglomeration process in the range of 80 °C to – 5 °C. |

| Model: |

| HOMOGENISING SYSTEMS LTD SFP SPCH-18-EP |

| Responsible Personnel: |

| Peter Švančárek, peter.svancarek@tnuni.sk |

| Laboratory mill for grinding solid materials |

| Function and use: |

| Laboratory mill for grinding and deagglomeration of high purity glass and ceramic powders by high energy grinding and subsequent size separation for applications in coatings or 3D printing as well as for the preparation of polycrystalline transparent materials with luminescent properties. |

| Technical specification: |

| The device allows grinding small sample volumes, with a volume of 500 ml – allows the separation of grinding bodies with a size range of at least 0,05 to 2 mm, – wet milling of solid materials with an output particle size (depending on the type of material) of less than 100 nm, – the equipment must be capable of grinding input material with a grain size of 200 μm |

| Model: |

| NETZSCH Laboratory mill MICRO – & MINISERIE |

| Responsible Employee: |

| Peter Švančárek <peter.svancarek@tnuni.sk> |

QUANTACHROME INSTRUMENTS AUTOSORB IQ-C-XR (1 STAT)

FUNCTION AND USE:

Autosorb iQ is the most advanced and flexible multifunctional, fully automatic gas adsorption analyzer, with 1 micropore analysis station, covering specific surface area and pore size distribution analysis using BET, t-plot, BJH and NLDFT methods. It is possible to perform various physisorption and chemisorption analysis. The autosorb iQ performs the most challenging measurements of non-porous, mesoporous, and microporous materials with accuracy and precision.

TECHNICAL SPECIFICATION:

- The autosorb iQ operates by measuring the quantity of gas adsorbed onto or desorbed from a solid surface at some equilibrium vapor pressure by the static volumetric method. The data are obtained by admitting or removing a known quantity of adsorptive gas into or out of a sample cell containing the solid adsorbent maintained at a constant temperature below the critical temperature of the adsorbate. As adsorption or desorption occurs the pressure in the sample cell changes until equilibrium is established. The quantity of gas adsorbed or desorbed at the equilibrium pressure is the difference between the amount of gas admitted or removed and the amount required to fill the space around the adsorbent (void space).

- The autosorb iQ AG has the capability of measuring adsorbed or desorbed volumes of nitrogen at relative pressures (P/Po) in the range 0.001 to slightly less than 1.0. When the micropore options are added, the lower limit is extended to 1×10-7 or 1×10-8. This volume-pressure data can be reduced by the autosorb iQ software into BET surface area (single and/or multipoint), Langmuir surface area, adsorption and/or desorption isotherms, pore size and surface area distributions, micropore volume and surface area using an extensive set of built-in data reduction procedures.

- ASiQwin software interfaces the autosorb iQ to a computer for data acquisition, data reduction, and archiving.

- The autosorb iQ has the ability to analyse physisorption for 90 hours without the need for refrigerant recharge.

MODEL:

QUANTACHROME INSTRUMENTS AUTOSORB IQ-C-XR (1 STAT.)

Model: 7

ASiQWin Version: 5.2x

Gas Sorption System

Responsible Person:

Zulema Vargas <zulema.vargas@tnuni.sk>

Equipment for granulation of powders by spray technology

Drying Instrument Mini Spray Dryer B-290

The equipment for drying suspensions, including both dispersed and dissolved powders. With a minimal material requirement of just 10 mL, conducting experiments becomes feasible and convenient. Additionally, the option to integrate a nitrogen circulation system enhances the capability of spray-drying organic solvents, thereby improving the overall effectiveness of the process.

Technical parameters:

Solvent: water or organic solvents

Drying atmosphere: air or inert gas – nitrogen

Max temperature: 220°C

Evaporation capacity:1.0 L / h H2O, higher for organic solvents

Final particle size:1 – 60 μm

Yield: up to 70 %

Model:

BÜCHI Labortechnik Mini Spray Dryer B-290

Responsible person:

Monika Michálková, monika.michalkova@tnuni.sk

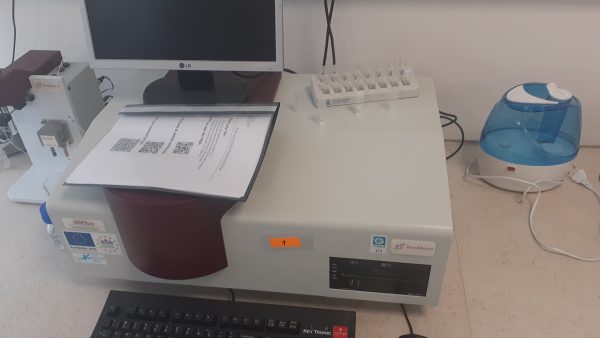

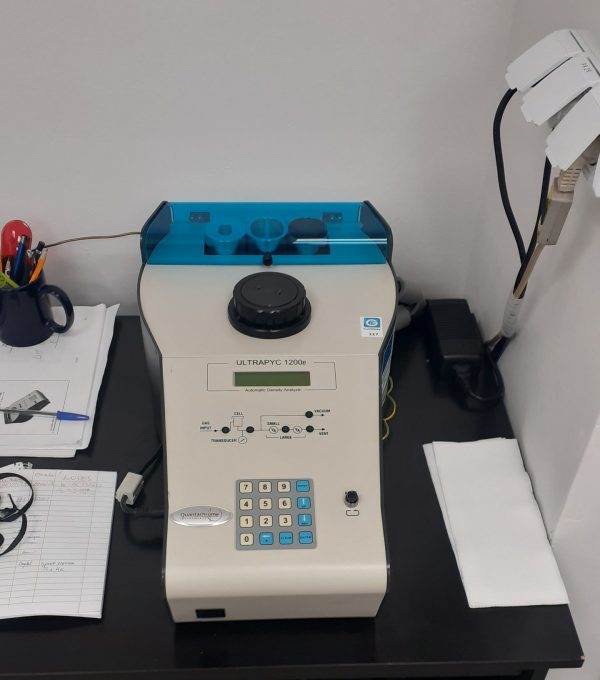

Helium Pycnometer

Function and use:

automatic gas pycnometer working in He atmosphere, used for measurement of true density and volume of solids.

Measurement of samples:

- pieces (bulks)

- powders

- fine powders (particle size from 50 nm to 50 μm)

- porous samples

Technical specification:

- volume of measured samples in range 1-135 cm3

- measurement accuracy ±0.001 g.cm-3

- output data in txt format

- protocol in pdf form

Model

Quantachrome Ultrapyc 1200e

Responsible person:

Anna Prnova <anna.prnova@tnuni.sk>

Equipment for measurement of thermally stimulated depolarisation currents, Novocontrol

Function and use:

Many key aspects of materials properties, e.g., molecular relaxations, phase transitions, glass temperatures, rate of curing, etc., are investigated by TSDC. The Quatro Cryosystem can be used with sample cells for dielectric and impedance spectroscopy.

Methods:

- thermally stimulated depolarization • thermally stimulated polarization • isothermal polarization time domain • isothermal conductivity time domain • relaxation map isotherm • relaxation map thermal window

Technical specification:

The Quatro Cryosystem

- Temperature range −160 °C … 400 °C

- Temperature ramps from 0.01 °C/min .. 20 °C/min

- 0.01 °C temperature stability

- Low nitrogen consumption, typically 1 l/hr at T> −100 °C

- control operation from ambient to 400 °C

Sample Cell:

- Integrated precision Pt100 temperature sensor

- Integrated interlock switch, enabling highvoltage application only if mounted into the temperature environment

- Sample diameter up to 40 mm

- Sample thickness from 0 to 4 mm

- Particular electrical insulation properties, enabling the accurate sample current measurements down to 10 fA

- Temperature range: 200 °C .. +250 °C

Model:

Novocontrol

Responsible Person:

Katarína Faturíková <katarína.faturikova@tnuni.sk>

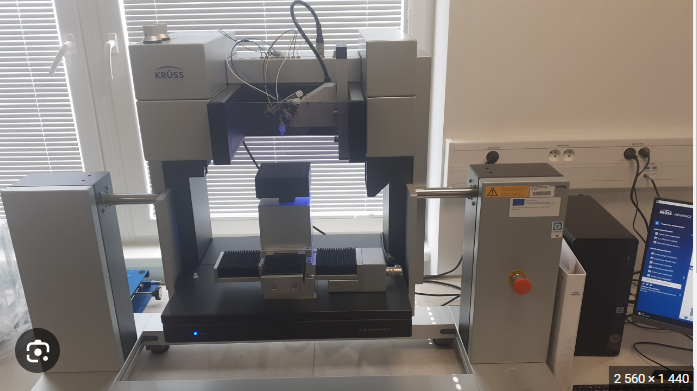

Drop Shape Analyzer

Function and use:

The Expert version of the DSA100 Drop Shape Analyzer enables solids and liquids in wetting and coating processes to be analyzed comprehensively. The high degree of automation with easy programmable procedures provides the contact angle and surface tension (SFE) results. It is also frequently used due to its versatility, its dosing solution with four (optional: up to eight) test liquids, and its scientific tools for analyzing the solid/liquid contact.

Technical specification:

- Sessile drop/captive bubble (contact angle 0 to 180°C; conic section, polynomial, circle, Young-Laplace, height-width models)

- Surface free energy of solids (models: equation of state, Zisman, Fowkes, Wu, Owens- Wendt-Rabel-Kaelble, Schultz-1, extended Fowkes, acid-base theory)

- Pendant drop (interfacial and surface tension, 0.01 to 2000 mN/m, Young-Laplace Model, types: static, dynamic)

- Maximum sambe space (320 mm × ∞ × 275 mm (W × D × H, without axes) )

Model:

KRÜSS DSA100 Expert

Responsible person:

Katarína Faturíková <katarina.faturikova@tnuni.sk>

Equipment for coating of solutions and suspensions by spray technology

Function and use:

The spray coater is a multifunctional industrial instrument employed for the purpose of depositing a uniform and thin film of liquid or suspension onto a given surface. The ND-SP-Precision Spray Coater operates by applying pressure to the material, causing it to atomize into small droplets or particles. These particles are subsequently dispersed over the desired substrate by a spraying mechanism. These mechanisms guarantee consistent distribution, accurate regulation of thickness, and effective utilisation of materials. The temperature of the substrate bed can be controlled up to a maximum of 250 degrees Celsius.

Model:

ND-SP Precision Spray Coating

Responsible person:

Ashokraja Chandrasekar; Ashokraja.chandrasekar@tnuni.sk

| Programmable DC Power supply for Anodization and Electrophoretic deposition coatings |

| Function and use: |

| This power supply is used for the purpose of developing oxide layer via anodization process on light weight metals such as aluminium, titanium and its alloys and for electrophoretic deposition of various metal, ceramics, glass-ceramic particles on conducting surfaces. This power supply can also function as constant current or voltage sources with basic voltage setting accuracy of 0.03% and basic voltage readback accuracy of 0.02% and 1mV and 0.1mA resolution. |

| Model: |

| Keithley DC power supply 2200-72-1 |

| Technical Specification:

Voltage – 0 to 72 V; < 0.01% + 2 mV Current – 0 to 1.2 A; < 0.05% + 0.5 mA Maximum power – 86 W |

| Responsible person: |

| Ashokraja Chandrasekar; Ashokraja.chandrasekar@tnuni.sk

|

Rheometer / Viscometer

Function and use:

Temperature modules with enhanced temperature control accuracy and expanded temperature module range for applications like starch and polymers.

Comprehensive accessory range to meet individual measuring needs like simultaneous measurements of rheology and, changes in the microscopic structure of samples (RheoScope Modul), and new measuring geometries and sample protection.

Technical specification:

- Pressure cells up to 400 bar

- Thermo Scientific™ RheoScope Modulefor the synchronous analysis of rheological properties and the microscopic structure of a sample

- CR, CS, CD mode in rotation

- CS and CD in oscillation

Model:

Haake Mars III

Responsible Person:

Ali Talimian<ali.talimian@tnuni.sk>

Pull-Off Adhesion Tester

Function and use:

The Elcometer 510 Automatic Pull-Off Adhesion Gauge accurately measures the adhesion strength of coatings on a variety of substrates. For most pull-off adhesion tests, the rate of pull is regulated manually, and the gauge automatically applies the pre-selected rate.

Technical specification:

– Fully adjustable pull rates: 0.1-1.4MPa/s

– Smooth load application up to 100MPa

– 10 and 20 mm diameter reusable dollies

Model:

Elcometer 510 Automatic Pull-Off Adhesion Gauge

Responsible personnel:

Dr. Omid Sharifahmadian, E-mail: omid.sharifahmadian@tnuni.sk

Microstructure characterisation

Optical Microscope NIKON LV 100 UDM

Function and use:

The Nikon LV 100 UDM Microscope features both epipscopic and diascopic illumination that can be controlled independently. The light is produced through dual, 50 Watt lamphouses that are capable of producing light that is the equivalent to 100W in other microscopes.

Technical specification:

It has both bright field and darkfield lighting techniques and is fitted with 5X, 10X, 20X, 50X and 100X objectives with a 1000X total magnification capability.

Model:

NIKON LV 100 UDM

Responsible Person:

Branislav Hruška, branislav.hruska@tnuni.sk

| Optical Microscope Nikon Eclipse ME 600 |

| Function and use: |

| Scientific microscope with attached CCD camera and fibre spectrometer, the possibility of observing the surface morphology of samples, also in polarised light, the possibility to observe processes under the microscope in life-time mode (e.g. crystallisation monitoring), the possibility of attaching a high-temperature stage. |

| Technical specification: |

| 5, 10, 20, 50 x lenses, movable x,y,z stage, possibility of working in polarized light, senanmontov, compensator, connection to CCD camera, Lucia software for image analysis, possibility to connect a fibre spectrometer. |

| Model: |

| Nikon Eclipse ME 600 |

| Responsible Personnel: |

| Branislav Hruška, branislav.hruska@tnuni.sk |

Confocal microscopy – Confocal microscope with the possibility of interferometric measurements

Function and use:

Confocal microscope enabling very fast and efficient 2D and 3D observation and precise evaluation of surfaces of solid bulk materials of irregular shape, thin films, fibres, powders, structures of various materials, i.e. characterization of prepared thin films in terms of their morphology and topography as well as basic optical properties and measurement of the thickness of transparent functional layers by interferometric measurement.

Technical specification:

The microscope allows confocal 2D and 3D imaging of surfaces and enable observation of samples: in bright field (BF), in polarised light, DIC – differential interference contrast, image formation: 2D images of surfaces and 2D measurements, 3D surface images and 3D measurements, image stacking: stacking multiple high-resolution fields of view,

– the microscope allows observation of specimens in a magnification range from at least 100x to at least 40 000x or higher,

– achieves lateral resolution £ of 260 nm or 37 Mpix and Z-axis resolution £ of 10 nm,

– the microscope shall be equipped with an LED or laser light source, with the possibility of extension to other sources with other wavelengths,

– equipped with a turret lens holder with a minimum of 5 positions,

– 4 objectives with magnifications of 10x, 20x, 50x, 100x

Model:

Sensofar Metrology S NEOX

Responsible Person:

Branislav Hruška <branislav.hruska@tnuni.sk>

| Inverted microscope with fluorescence |

| Function and use: |

| Inverted fluorescence optical microscope allowing measurements in transmitted light in brightfield and phase contrast and optionally in reflected light in epi fluorescence |

| Technical specification: |

| Equipped with a turret head for 4 lenses, 4 long working distance objectives allowing measurements at magnifications, 4x or 5x – 11 mm, 10x – 8.5 mm, 20x – 4,5 mm, 40x – 2.5 mm. – Binocular tube with eyepieces with a minimum magnification of 10x and a field of view width of 22 mm with a dioptric correction of ±5 diopters, – equipped with one port for connecting a digital camera with an optical path ratio of at least 100-0/0-100 |

| Model: |

| Eclipse Ts2R-FL/Nikon |

| Responsible Personnel: |

| Zuzana Neščáková <zuzana.nescakova@tnuni.sk> |

Innova®Atomic Force Microscope

Function and use:

The atomic force microscope is an instrument designed to detect local mechanical, thermo-mechanical and electrical properties of materials. Operational modes for analysis of samples in air and/or liquid: Contact mode/lateral force microscopy, AC mode/tapping mode with phase control and Q-control function, electrical force microscopy, surface potential microscopy, magnetic forces, piezoresponse forces, tan δ loss angle imaging, force spectroscopy and mapping, nanolithography, nanomanipulation. The system shall have the capability of mapping and capturing force curves at high speed (at least 300 force curves per second).

Technical specification:

The system shall have the capability of mapping and capturing force curves at high speed (at least 300 force curves per second).

Model:

Innova®Atomic Force Microscope

Responsible person:

Branislav Hruška branislav.hruska@tnuni.sk

Profilometer

Function and use:

All necessary surface finish capabilities, such as the basic roughness and waviness characteristics, and form error analyses, are provided by the profilometer.

Technical specification:

- The instrument’s vertical range and resolution are 1 mm and 16 nm, respectively.

- Its 50mm horizontal traverse is suitable for a wide range of applications.

Model:

Taylor Hobson, Intra Touch

Responsible person:

Omid Sharifahmadian, omid.sharifahmadian@tnuni.sk

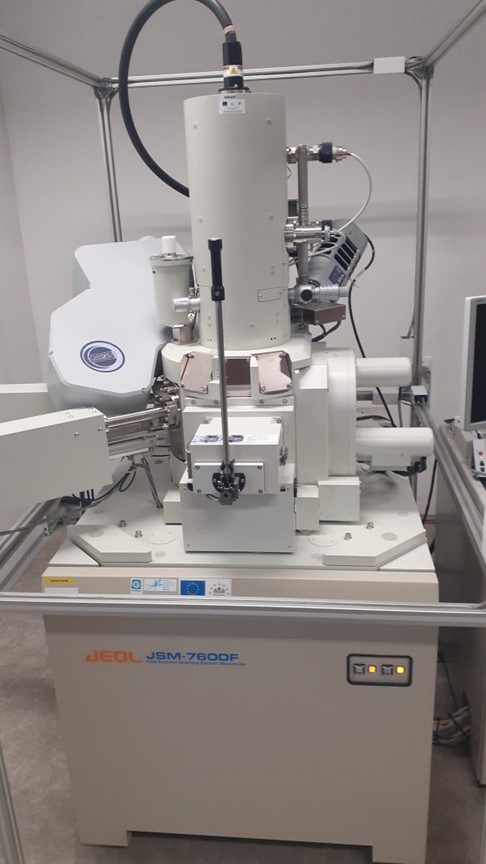

Scanning Electron Microscope, JEOL JSM-7600 F

Function and use:

Instrument for detailed chemical and microstructural analysis of ceramic composites, identification of the distribution of secondary phases in composites, identification and characterization of corroded surfaces and corrosion products of glass and ceramic materials, analysis of inhomogeneities in glass, characterization of crystallization products in the study of glass crystallization mechanisms.

Technical specification:

Microscope type: SEM with Field emission gun- Schottky type

Accelerating voltage 0.1 to 30 kV

Resolution (SE): 1.0 nm (15 kV), 1.5 nm (1 kV) in GB mode, 0.6 nm (30 kV) attainable in STEM

Magnification: 25 to 1,000,000x (printed as a 120mm x 90mm micrograph)

Beam current: 1 pA to 200 nA at 15 kV

Aperture angle control lens: Integrated

Detectors: Upper and lower detectors SEI, retractable LABe (BEI), EDXS, WDXS, retractable EBSD

Energy Filter: In column r-filter for upper SE detector

Gentle beam: Integrated beam deceleration

Digital images 1,280 x 960, 2,560 x 1,920, 5,120 x 3,840

Specimen exchange chamber: Single step loading/unloading

Specimen stage: Eucentric, 5 axis motor drive

Model:

Scanning Electron Microscope, JEOL JSM-7600 F

Responsible Personnel:

Peter Švančárek, peter.svancarek@tnuni.sk

Analytical Scanning Electron Microscope with EDXS detector JEOL JSM-IT500

Electron microscopy – Scanning electron microscope with EDS analyzer

Function and use:

Laboratory scanning electron microscope for microstructural and chemical analysis of materials with a module that allows cooling (freezing) of samples to low temperatures, enabling the measurement of samples that are also sensitive to pressure or temperature, such as biological specimens and biomaterials containing biopolymers.

Technical specification:

Resolution: High vacuum mode: 3.0 nm (30 kV) 15.0 nm (1.0 kV); Low vacuum mode: 4.0 nm (30 kV BED)

Direct magnification: x5 to x300,000 (Defined with a display size of 128 mm x 96 mm)

Displayed magnification: ×14 to ×839,724 (on the monitor-defined with a display size of 358 mm x 269 mm)

Electron gun: W filament, fully automatic gun alignment

Accelerating voltage: 0.3kV to 30kV

Probe current: 1 pA to 1 μA

Low-vacuum pressure adjustment:10Pa to 650Pa

Objective lens aperture: 3-stage, with XY fine adjustment function

Automatic functions: Filament adjustment, Gun alignment, Focus / Stigmator / Brightness / Contrast

Detectors: SE, BED, EDXS

Maximum specimen size: 200mm dia. x 75mm height

Specimen stage: Large eucentric type X: 125 mm, Y: 100 mm, Z: 80 mm

Tilt: -10° to 90° Rotation: 360°

Model:

Analytical Scanning Electron Microscope JEOL JSM-IT500

Responsible Personnel:

Peter Švančárek, peter.svancarek@tnuni.sk

Chemical analysis

X-RAY PHOTOELECTRON SPECTROSCOPY (XPS)

FUNCTION AND USE:

This system offers fully automatic surface analysis with high throughput, providing detailed chemical and elemental information. XPS measures surface properties within a few atomic layers (1-10 nm), that differs from bulk composition analysis methods like energy dispersive spectroscopy (EDS). The primary functions of XPS include a) the composition of materials surfaces (element identification), b) the abundance of elements on surfaces (quantitative analysis), and c) chemical state measurement through binding energies of elements, which is related to the nature and strength of their chemical bonds. XPS is a versatile method and can characterize the surface of various materials, including minerals, organic compounds, semiconductors, thin films, and coatings for both research and industrial applications.

TECHNICAL SPECIFICATION:

- Powerful X-ray source (monochromated, microfocused, low power Al K-Alpha).

- X-ray spot size can be set between 10 to 400 μm (adjustable in 5 μm increments).

- Maximum sample range of 60 mm (L) x 60 mm (W), with sample thickness up to 20 mm.

- Dual beam flood gun for reliable charge compensation.

- Depth profiling of materials using EX06 monatomic ion source.

- SnapMap feature enables quantified chemical stage images with high resolution.

- Hemispherical analyzer with 128-channel detector, 180°, and double focussed.

- Tilt module sample holder.

- Fast sample loading and data acquisition.

- Device control, data processing and reporting done through Avantage software.

MODEL:

ThermoFisher Scientific Nexsa G2 surface analysis system

Responsible Person:

Kamalan Mosas <kamalan.mosas@tnuni.sk>

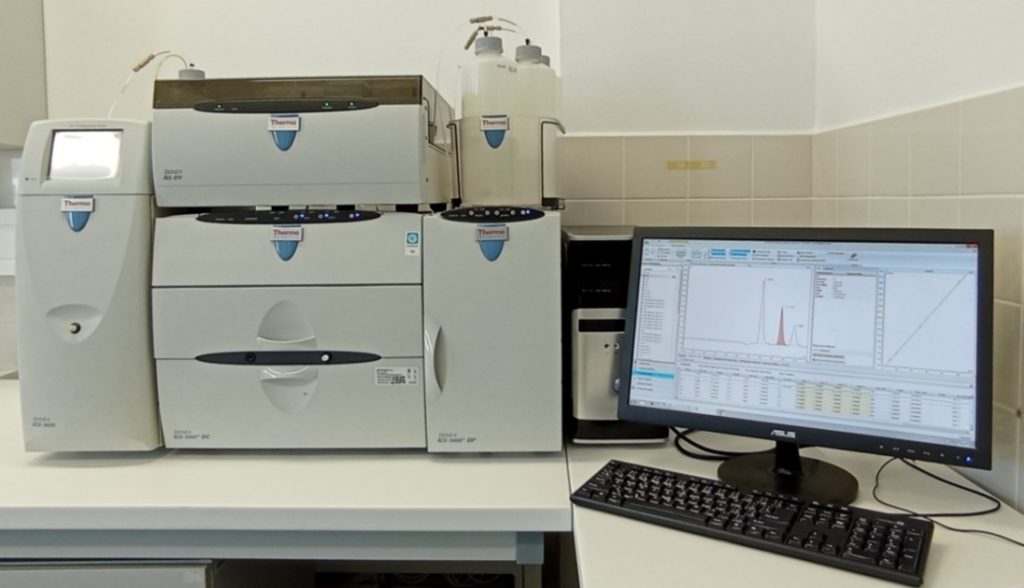

Ion chromatography system Dionex™ ICS-5000+

Function and use:

- Ion chromatography system DIONEX ICS-5000+ is designed to measure concentration of ionic species in the liquid samples by separating them based on their interaction with a stationary phase and next elution with extraction liquid running through the column. Ionic species are separated differently depending on species type and size.

- The current configuration is set up for the qualitative and quantitative determination of anions (chloride, fluoride, bromide, phosphate, nitrate, nitrite and sulfate) and cations (lithium, sodium, ammonium, potassium, calcium and magnesium) in various liquid matrices.

Technical specification:

- Isocratic pump flow

- Conductivity detector

- AS-DV autosampler

- Chromeleon 7 System Control

- 2mm diameter columns AS14, CS12A, guard columns AG14, CG12A

Model:

- Ion chromatography system Dionex™ ICS-5000+

Responsible person:

- Lenka Buňová lenka.bunova@tnuni.sk

Microwave Digestion System, Berghof Speedwave 4

Function and use:

- Microwave digestion system is designed to perform chemical digestion procedure under high pressure and temperature conditions. Using of a suitable digestion reagent at increased temperature in teflon vessels permeable with regard to microwaves, solid material is decomposted.

- Digestion solution are directly heated through the absorption of the microwave radiation by the polar digestion reagent.

- Sample preparation mainly for ICP spectroscopy procedures

Technical specification:

- Pressure digestion at temperatures up to 230°C (short term 300°C) and pressures up to a max. of 100 bar.

- Two rotors with two types of vessels DAP-100+ (chemical resistance to all mineral acids including hydrofluouric acid) and DAK-100/4

- Temperature and pressure monitoring of all samples in real time

- Up to 8/12 vessels/samples in one run

- Adapters for evaporating and concentrating digestion solutions

Model:

Berghof Speedwave 4

Responsible person:

Lenka Buňová lenka.bunova@tnuni.sk

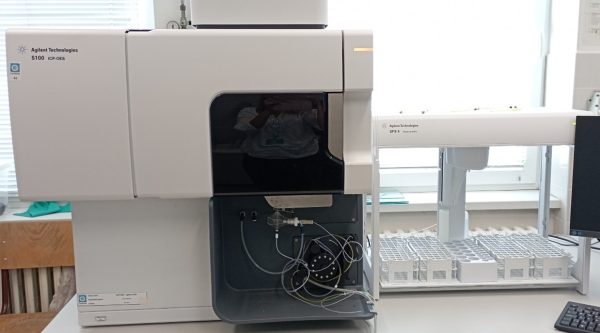

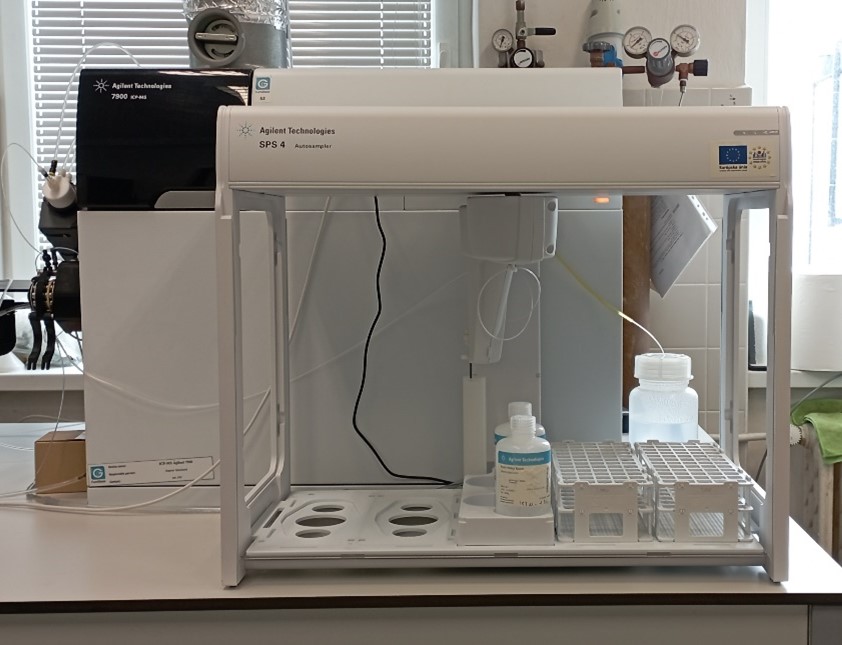

ICP OES Varian Vista MPX:

Function and use

The ICP-OES analysis technique (Inductively Coupled Plasma Optical Emission Spectroscopy) uses a high frequency inductively coupled plasma as a light source and is used for elemental analysis of sample solutions.

The Vista-MPX system captures all the spectral image in a single reading – designed to provide the productivity of simultaneous ICP-OES. The system can be used to detect and quantify most inorganic elements.

Technical specification

- Radial viewed plasma, vertical torch

- Gas flow control using a manual pressure regulator.

- PC-controlled peristaltic pump allowing the addition of reagents or internal standards for optimal calibration and measurement.