New papers published at FunGlass/ May 2020

We would like to draw your attention to the new papers of our researchers presenting their research results achieved in collaboration with the colleagues from FunGlass partners´ institutions. The papers are published in peer-reviewed and highly cited journals:

![]() Singarapu, B.- Galusek, D.- Durán, A.- Pascual, M.J.: Glass-Ceramics Processed by Spark Plasma Sintering (SPS) for Optical Applications. In: Applied Sciences. 2020, 10(8), 2791. https://www.mdpi.com/2076-3417/10/8/2791

Singarapu, B.- Galusek, D.- Durán, A.- Pascual, M.J.: Glass-Ceramics Processed by Spark Plasma Sintering (SPS) for Optical Applications. In: Applied Sciences. 2020, 10(8), 2791. https://www.mdpi.com/2076-3417/10/8/2791

Abstract: This paper presents a review on the preparation of glass-ceramics (GCs) and, in particular, transparent GCs by the advanced processing technique of spark plasma sintering (SPS). SPS is an important approach to obtain from simple to complex nanostructured transparent GCs, full densification in a short time, and highly homogeneous materials for optical applications. The influence of the different processing parameters, such as temperature, pressure, sintering dwell time on the shrinkage rate, and final densification and transparency, are discussed and how this affects the glass material properties. Normally, transparent glass-ceramics are obtained by conventional melt-quenching, followed by thermal treatment. Additionally, the GC scan is produced by sintering and crystallization from glass powders. Hot pressing techniques (HP) in which the source of heating is high-frequency induction can be also applied to enhance this process. In the case of transparent ceramics and glass-ceramics, spark plasma sintering is a promising processing tool. It is possible to enhance the material properties in terms of its compactness, porosities, crystallization, keeping the size of the crystals in the nanometric scale. Moreover, the introduction of a high concentration of active gain media into the host matrix provides functional glass-ceramics systems with enhanced luminescence intensity through reducing non-radiative transitions like multi phonon relaxation (MPR) and cross relaxations (CR), thus providing longer lifetimes. More effort is needed to better understand the sintering mechanisms by SPS in transparent GC systems and optimize their final optical performance.

(This article belongs to the Special Issue Photonic Glass-Ceramics: Fabrication, Properties and Applications)

K. Drdlikova- R. Klement– D. Drdlik- D. Galusek– K. Maca: Processing and properties of luminescent Cr3+ doped transparent alumina ceramics. In: Journal of the European Ceramic Society. 2020, Vol. 40, Issue 7, p. 2573-2580 https://doi.org/10.1016/j.jeurceramsoc.2019.11.010

K. Drdlikova- R. Klement– D. Drdlik- D. Galusek– K. Maca: Processing and properties of luminescent Cr3+ doped transparent alumina ceramics. In: Journal of the European Ceramic Society. 2020, Vol. 40, Issue 7, p. 2573-2580 https://doi.org/10.1016/j.jeurceramsoc.2019.11.010

Abstract: Transparent Cr2O3-doped alumina ceramics were prepared by slip casting, followed by pre-sintering in ambient atmosphere and hot isostatic pressing. The effect of dopant concentration on material properties, including microstructure and optical properties was evaluated. Real in-line transmittance in the range of 20–44 % was measured for the ceramics with the mean grain size <520 nm: the transmittance decreased with increasing grain size and Cr content. The excitation spectra consisted of two broad bands with maxima at 404 nm and 558 nm, corresponding to 4A2g → 4T1g and 4A2g → 4T2g transitions of Cr3+ ions in octahedral sites of α-Al2O3. The intensive deep red narrow emissions under violet/green light excitation, R-lines (2Eg → 4A2g transition), were observed at 692.5 nm and 693.8 nm, that are very close to ruby single crystal. The highest emission was achieved at the Cr3+ concentration of 0.4 at.%. The luminescence decay curves exhibited single-exponential behaviour with decay times of ∼3.6 ms.

M. Michálková, J. Kraxner, M. Michálek, D. Galusek: Preparation of translucent YAG glass/ceramic at temperatures below 900 °C. In: Journal of the European Ceramic Society. 2020, Vol. 40, Issue 7, p. 2581- 2585.

M. Michálková, J. Kraxner, M. Michálek, D. Galusek: Preparation of translucent YAG glass/ceramic at temperatures below 900 °C. In: Journal of the European Ceramic Society. 2020, Vol. 40, Issue 7, p. 2581- 2585.

https://doi.org/10.1016/j.jeurceramsoc.2019.11.011

Abstract: The work presented here deals with the preparation of bulk yttrium aluminium garnet (YAG) glass-ceramics and YAG ceramics from glass microspheres with a YAG composition. Sol-gel prepared YAG powder was fed into a high temperature methane-oxygen flame where the particles melted and glass microspheres, with a YAG composition, were formed. Viscous flow sintering of the microspheres was then performed to prepare bulk YAG glass-ceramics or ceramics in a hot press.

Rapid crystallization of YAG glass was traced during hot pressing through a change in the heating rate slope due to release of latent (crystallization) heat. This allowed control of crystallization and enabled preparation of YAG-based materials with different amounts of residual glass. YAG ceramic with relative density of 94.2 % was prepared at 891 °C without isothermal heating; additionally, YAG glass-ceramic reached relative density > 99 % at temperature 815 °C without isothermal heating.

![]() I. Petríková- M. Parchovianský- P. Švančárek– M. L. Leite- G Motz- D. Galusek: Passive filler loaded polysilazane‐derived glass/ceramic coating system applied to AISI 441 stainless steel, part 1: Processing and characterization. In: Int. Journal of Applied Ceramic Technology, 2020,17, p. 998–1009.

I. Petríková- M. Parchovianský- P. Švančárek– M. L. Leite- G Motz- D. Galusek: Passive filler loaded polysilazane‐derived glass/ceramic coating system applied to AISI 441 stainless steel, part 1: Processing and characterization. In: Int. Journal of Applied Ceramic Technology, 2020,17, p. 998–1009.

https://doi.org/10.1111/ijac.13417

Abstract: This study describes an oxidation and corrosion resistant environmental barrier coating (EBC) applied to an AISI 441 stainless steel substrate. For this purpose, four polymer‐derived ceramic (PDC) coating systems were developed. These coating systems consisted of a bond coat applied by dip coating, and a top‐coat that was loaded with passive fillers and deposited by spray coating. The microstructures of the coatings were investigated using optical microscopy and scanning electron microscopy, including energy dispersive spectroscopy (EDS). X‐ray powder diffraction (XRD) was used to investigate the phase composition of the coatings. The optimized composite top coatings were prepared from the preceramic polymer HTT1800, filled with yttria‐stabilized zirconia and a specially tailored Al2O3–Y2O3–ZrO2 (AYZ) passive filler, and commercial barium silicate glasses were used as sealing agents. After thermal treatment in air at 750°C, uniform and crack‐free composite coatings on stainless steel substrates were developed, with thicknesses of up to 93 μm. Oxidation tests, which were performed at 850°C in synthetic air, showed that every tested coating system remained undamaged by oxidation and showed good bonding to the metal substrate.

R. Svoboda- Z. Olmrová Zmrhalová- D. Galusek– D. Brandová- J. Chovanec: Thermal decomposition of mixed calcium oxalate hydrates – kinetic deconvolution of complex heterogeneous processes. In: Phys. Chem. Chem. Phys., 2020, 22, p. 8889-8901. DOI: 10.1039/c9cp06867h

R. Svoboda- Z. Olmrová Zmrhalová- D. Galusek– D. Brandová- J. Chovanec: Thermal decomposition of mixed calcium oxalate hydrates – kinetic deconvolution of complex heterogeneous processes. In: Phys. Chem. Chem. Phys., 2020, 22, p. 8889-8901. DOI: 10.1039/c9cp06867h

Abstract: Differential scanning calorimetry (DSC), thermogravimetry (TG) and in situ XRD were used to study dehydration and consequent decomposition reactions of mixed calcium oxalate hydrates. As the complex dehydration kinetics exhibited certain trends with respect to the applied heating rate, the modified multivariate kinetic analysis approach (based on averaged curve-by-curve optimizations) was employed to obtain a full kinetic description of the data. The Šesták–Berggren equation was used to model the two consequent dehydration reactions. Good agreement was found between the kinetic parameters calculated from the DSC and TG data – approximate values of activation energies were 68 and 81 kJ mol−1 for the trihydrate → monohydrate and monohydrate → anhydride transformations, respectively. A procedural methodology was developed to predict both dehydration kinetics and hydrate content ratios. For the calcium oxalate decomposition the TG technique provided very precise single-step prediction with an activation energy of 180 kJ mol−1. DSC on the other hand provided complex information on joint decomposition and carbon monoxide oxidation reactions – the proposed reaction mechanism includes completion of two reaction paths composed of consequent chemical reactions. A mechanistic view of the complex reaction path is discussed in terms of the diffusion barrier limiting the oxidation step.

R. Sayyad- M. Ghambaria- T. Ebadzadeh- A. H. Pakseresht– E. Ghasali : Preparation of Ag/reduced graphene oxide reinforced copper matrix composites through spark plasma sintering: An investigation of microstructure and mechanical properties. In: Ceramics International, 2020, Vol. 46, Issue 9, p. 13569-1

https://doi.org/10.1016/j.ceramint.2020.02.142

Abstract: The reduced graphene oxide (rGO) decorated with Ag nanoparticles was synthesized by the chemical reduction of graphene oxide in an aqueous solution containing AgNO3, in the presence of hydrazine hydrate as a reducing agent. The reduction of graphene oxide was confirmed by FT-IR and raman spectroscopy analyses. The x-ray diffraction pattern and UV–visible investigations demonstrated the formation of Ag particles on the surface of rGO sheets. After successful decoration, the Ag/rGO nano-composite was used as the reinforcement in the copper matrix composite. Cu–Ag/rGO composites with different percentages of Ag/rGO (0.4, 0.8, 1.6 and 3.2 vol%.) were prepared by mechanical milling and spark plasma sintering (SPS). The effects of the Ag/rGO content on the consolidation process, micro-hardness, bending strength and also, fracture surface of the prepared samples were then investigated. The three-point bending strength of the sintered samples was increased from 285 to 472 MPa by the addition 0.8 vol%. of Ag/rGO, as compared to the pure Cu. Moreover, increasing the reinforcement content to the 3.2 vol%. Ag/rGO led to decreasing the bending strength to 433 MPa. The highest micro-hardness (81 Hv) was obtained for the composite sample containing the 1.6 vol%. Ag/rGO. By increasing Ag/r-GO as the reinforcement (3.2 vol%.), the Vickers hardness was decreased to 69 Hv. Also, investigation of the fracture surface morphology showed transformation of fracture mechanism from plastic changes to brittle ones by raising the Ag/rGO content volume from 0.8 to 1.6 vol %.

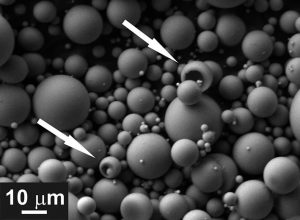

A. Prnová- J. Valúchová- N. Mutlu- M. Parchovianský- R. Klement, A. Plško- D. Galusek: Thermal behaviour and photoluminescence properties of Er- and Nd-doped yttrium aluminate glasses. In: Journal of Thermal Analysis and Calorimetry. 2020

A. Prnová- J. Valúchová- N. Mutlu- M. Parchovianský- R. Klement, A. Plško- D. Galusek: Thermal behaviour and photoluminescence properties of Er- and Nd-doped yttrium aluminate glasses. In: Journal of Thermal Analysis and Calorimetry. 2020

https://doi.org/10.1007/s10973-020-09816-3

Abstract: Yttrium aluminate glasses (76.8 mol% of Al2O3, 23.2 mol% of Y2O3) doped with Er3+ and Nd3+ ions at different concentration levels (0.25 mol%, 0.5 mol% and 0.75 mol% Er2O3/Nd2O3) were prepared by flame synthesis in the form of glass microspheres. The prepared samples were XRD amorphous, without presence of any crystalline phases in measured patterns. The two exothermic effects (~ 940, ~ 1010 °C), which can be assigned to the two steps of YAG crystallization, were observed in the DSC records of all prepared samples. The high temperature XRD measurements showed YAG (900–1200 °C) and α-Al2O3 (1300–1450 °C) phase crystallization. The emission spectra were measured in the VIS and NIR regions for Er-doped samples and in the NIR region for Nd-doped samples. All measured emission spectra contain of characteristic bands due to the typical 4f–4f transitions within the Er3+ and Nd3+ ions. Comparison of the measured intensities of Er-doped samples made it evident that the highest intensities were obtained for the 0.5 mol% Er2O3-doped sample (in both the NIR and VIS spectral regions). The maximum intensity for Nd-doped samples was found when the sample was doped with 0.75 mol% of Nd2O3. The slowly increasing of emission intensities in samples after 20 min annealing at 1000 °C and Stark splitting of emission bands in samples after 40 and 60 min annealing at 1000 °C and after 20, 40 and 60 min annealing at 1500 °C was observed.

SEM micrograph of AYE-Er0.5 prepared microspheres. The hollow microspheres are marked by arrows