Articles published by FunGlass people

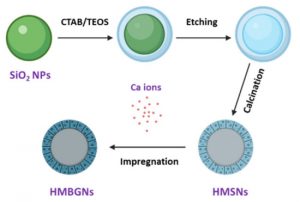

Mutlu, N.; Beltrán, A.M.; Nawaz, Q.; Michálek, M.; Boccaccini, A.R.; Zheng, K.: Combination of Selective Etching and Impregnation toward Hollow Mesoporous Bioactive Glass. In: Nanomaterials 2021, 11, 1846.

Mutlu, N.; Beltrán, A.M.; Nawaz, Q.; Michálek, M.; Boccaccini, A.R.; Zheng, K.: Combination of Selective Etching and Impregnation toward Hollow Mesoporous Bioactive Glass. In: Nanomaterials 2021, 11, 1846.

https://doi.org/10.3390/nano11071846

Abstract: In this study, binary SiO2-CaO hollow mesoporous bioactive glass nanoparticles (HMBGNs) are prepared by combing selective etching and impregnation strategies. Spherical silica particles (SiO2 NPs) are used as hard cores to assemble cetyltrimethylammonium bromide (CTAB)/silica shells, which are later removed by selective etching to generate a hollow structure. After the removal of CTAB by calcination, the mesoporous shell of particles is formed. Calcium (Ca) is incorporated into the particles using impregnation by soaking the etched SiO2 NPs in calcium nitrate aqueous solution. The amount of incorporated Ca is tailorable by controlling the ratio of SiO2 NPs:calcium nitrate in the soaking solution. The produced HMBGNs are bioactive, as indicated by the rapid formation of hydroxyapatite on their surfaces after immersion in simulated body fluid. In a direct culture with MC3T3-E1 cells, HMBGNs were shown to exhibit concentration-dependent cytotoxicity and can stimulate osteogenic differentiation of MC3T3-E1 cells at concentrations of 1, 0.5, and 0.25 mg/mL. Our results indicate that the combination of selective etching and impregnation is a feasible approach to produce hierarchical HMBGNs. The produced hollow particles have potential in drug delivery and bone tissue regeneration applications, and should be further investigated in detailed in vitro and in vivo studies.

A. Feriancová, A. Dubec, J. Pagáčová, I. Papučová, K. Moricová, M. Žitňan: Preparation and application of modified organo-kaolinite by microwave-assisted irradiation. In: Applied Clay Science, Volume 213, 2021, 106259, ISSN 0169-1317.

A. Feriancová, A. Dubec, J. Pagáčová, I. Papučová, K. Moricová, M. Žitňan: Preparation and application of modified organo-kaolinite by microwave-assisted irradiation. In: Applied Clay Science, Volume 213, 2021, 106259, ISSN 0169-1317.

https://doi.org/10.1016/j.clay.2021.106259

Abstract: From the aspect of the modern approach, it is necessary to increase the intercalation efficiency for the objective of widespread market application of kaolinite. The submitted article deals with the microwave-assisted modification of kaolinite (Kaol). Using potassium acetate (KAc) solution and dimethyl sulphoxide (DMSO), Kaol was treated chemically by a microwave radiation at different time intervals at a set constant temperature. Different techniques, such as X-ray diffraction patterns analysis (XRD), Fourier transformed infrared spectroscopy (FT-IR) spectroscopy, thermogravimetry/ differential scanning calorimetry (TG/DSC), and scanning electron microscopy (SEM) were used to characterize Kaol and modified kaolinite samples. The modification was observed after microwave radiation was applied for a short time (30 min). Finally, for the supplementation of the results, the model rubber compounds, filled with Kaol, modified Kaol-KAc and Kaol-DMSO samples in the amount of 10 phr (parts per hundred rubber), were prepared. The effect of modified kaolinite on the curing characteristics and mechanical properties in sulphur-cured natural rubber (NR) compounds was investigated. Partial substitution of carbon black with Kaol-DMSO led to the lower minimum torque and the acceleration of the crosslinking reaction. Moreover, the NR vulcanizates containing Kaol-DMSO showed higher tensile strength and hardness along with high maximum torque that are indicators of the reinforcing effect of the modified kaolinite.

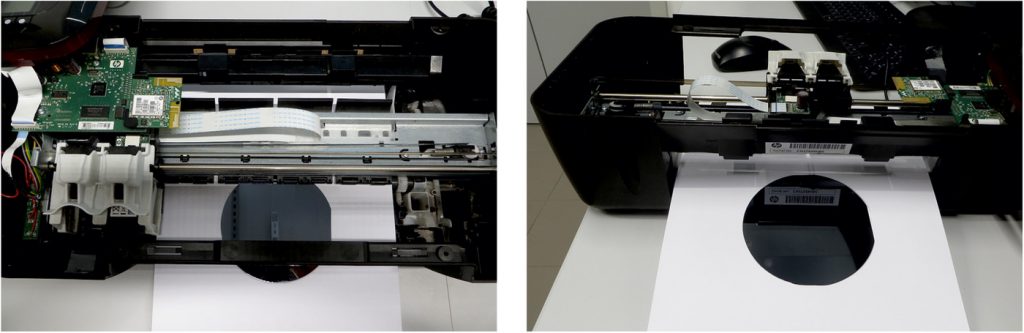

Žitňan, M, Müller, L, Zub, K, Schubert, US, Galusek, D, Wondraczek, L.: Low-cost inkjet printing of thin-film mullite structures. In: International Journal of Applied Glass Science. 2021; 1– 8.

Žitňan, M, Müller, L, Zub, K, Schubert, US, Galusek, D, Wondraczek, L.: Low-cost inkjet printing of thin-film mullite structures. In: International Journal of Applied Glass Science. 2021; 1– 8.

https://doi.org/10.1111/ijag.16537

Abstract: A commodity inkjet printer was modified to print layered ceramic structures on stiff glass substrates, using inks in the form of sols with mullite stoichiometry. The sol composition was optimized in terms of ink viscosity, surface tension, and evaporation properties. The ink was then fed into a multi-nozzle commodity printer head and deposited by ink-jetting. Thin lines without bulges with a thickness of ∼1.8 μm with concave profile and a line width of ∼100 μm were successfully printed on fused silica substrates. The presence of mullite was confirmed by Raman spectroscopy and XRD after sintering of printed structures.

Martin Blaško, Lukáš F. Pašteka, and Miroslav Urban: DFT Functionals for Modeling of Polyethylene Chains Cross-Linked by Metal Atoms. DLPNO–CCSD(T) Benchmark Calculations. In: The Journal of Physical Chemistry, 2021, 125 (34), p. 7382-7395

Martin Blaško, Lukáš F. Pašteka, and Miroslav Urban: DFT Functionals for Modeling of Polyethylene Chains Cross-Linked by Metal Atoms. DLPNO–CCSD(T) Benchmark Calculations. In: The Journal of Physical Chemistry, 2021, 125 (34), p. 7382-7395

https://doi.org/10.1021/acs.jpca.1c04793

Abstract: Density functional theory (DFT) functionals for calculations of binding energies (BEs) of the polyethylene (PE) chains cross-linked by selected metal atoms (M) are benchmarked against DLPNO–CCSD(T) and DLPNO–CCSD(T1) data. PEX-M-PEX complexes as compared with plain parallel PEX···PEX chains with X = 3–9 carbon atoms are model species characterized by a cooperative effect of covalent C-M-C bonds and interchain dispersion interactions. The accuracy of DLPNO–CC methods was assessed by a comparison of BEs with the canonical CCSD(T) results for small PE3-M-PE3 complexes. Functionals for PEX···PEX and closed-shell PEX-M-PEX complexes (M = Be, Mg, Zn) were benchmarked against DLPNO–CCSD(T) BEs; open-shell complexes (M = Li, Ag, Au) were benchmarked against the DLPNO–CCSD(T1) method with iterative triples. Three dispersion corrections were combined with 25 DFT functionals for calculations of BEs with respect to PEX-M and PEX fragments employing def2-TZVPP and def2-QZVPP basis sets. Accuracy to within 5% for the closed-shell PEX-M-PEX complexes was achieved with five functionals. Less accurate are functionals for the open-shell PEX-M-PEX complexes; only two functionals deviate by less than 15% from DLPNO–CCSD(T1). Particularly problematic were PEX-Li-PEX complexes. A reasonable overall performance across all complexes in terms of the mean absolute percentage error is found for the range-separated hybrid functionals ωB97X-D3 and CAM-B3LYP/D3(BJ)-ABC.

M. Chromčíková, B. Hruška, A. Nowicka, R. Svoboda, M. Liška: Role of modifiers in the structural interpretation of the glass transition behavior in MgO/BaO-Al2O3-P2O5 glasses. In: Journal of Non-Crystalline Solids, Volume 573, 2021, 121114, ISSN 0022-3093.

M. Chromčíková, B. Hruška, A. Nowicka, R. Svoboda, M. Liška: Role of modifiers in the structural interpretation of the glass transition behavior in MgO/BaO-Al2O3-P2O5 glasses. In: Journal of Non-Crystalline Solids, Volume 573, 2021, 121114, ISSN 0022-3093.

https://doi.org/10.1016/j.jnoncrysol.2021.121114

Abstract: Thermomechanical analysis, differential scanning calorimetry and Raman spectroscopy were used to study the role of the modifying oxides on the glass transition behavior of the MgO/BaO-Al2O3-P2O5 glasses. In case of the volumetric changes associated with the glass-liquid transformation, a complex description combining the effects of viscosity, thermal expansion and structural relaxation was successfully applied to the thermomechanical data based on non-linear optimization of the involved variables. For the enthalpy relaxation data, a novel simulation-comparative method was developed to accurately determine the kinetic parameters of the Tool-Narayanaswamy-Moynihan relaxation model, overcoming the difficulties associated with the commonly encountered instrumental distortions of the experimental data. In most cases, the modifying oxides had the dominant role, as compared to the primarily cross-linking effect of the Al2O3 oxide, in determination of the physico-chemical properties of the studied glasses. Differences between the magnesium and barium phosphates were consistent with the concept of larger size Ba2+ ions leading to the higher disorganization and diversification of the phosphate glass matrix. Compositional trends in the measured quantities were correlated with the representation of the particular structural units occurring in the MgO/BaO-Al2O3-P2O5 glasses.

![]() Michálková J., Chromčíková M., Hruška, B. Peterson, J., Liška M.: Contactless thermodilatometry of glass cullet. In: Ceramics-Silikáty 65, (3) 235 – 238 (2021)

Michálková J., Chromčíková M., Hruška, B. Peterson, J., Liška M.: Contactless thermodilatometry of glass cullet. In: Ceramics-Silikáty 65, (3) 235 – 238 (2021)

Abstract: Contactless dilatometry was used for the thermal analysis of a set of glass cullet samples collected in the surroundings (including the forest, gardens, etc.) of the Janštejn glass factory. The collected set of samples covered the time period of approximately one century. The glass composition was measured by X-ray fluorescence spectroscopy. A method of verifying the correctness of the contactless dilatometry results based on the Priven 2000 evaluation of thermal properties was proposed and verified.

![]() Pánová, K.; Jílková, K.; Rohanová, D.; Lahodný, F.; Galusková, D.; Míka, M.: Melting Process and Viscosity of Bohemian Historical Glasses Studied on Model Glasses. In: Minerals 2021, 11, 829.

Pánová, K.; Jílková, K.; Rohanová, D.; Lahodný, F.; Galusková, D.; Míka, M.: Melting Process and Viscosity of Bohemian Historical Glasses Studied on Model Glasses. In: Minerals 2021, 11, 829.

https://doi.org/10.3390/min11080829

(This article belongs to the Special Issue Characterization of Archaeological and Historic Vitreous Materials)

Abstract: Analyzing the chemical composition of archaeological glasses can provide an insight into their provenance and raw materials used in their making. However, to the authors’ knowledge, the historical production process itself and melting characteristics of the glasses have not yet been extensively investigated. The main focus of this paper is to describe the melting process of three main types of Bohemian historical glasses: Gothic (14th–1st half of 16th c.); Renaissance (16th–17th c.); and Baroque (end of 17th–18th c.). The model glasses were prepared from natural raw materials and processes that take place during melting were investigated using optical microscopy, SEM-EDS, XRD, and DTA-TG methods. Furthermore, the viscosity of model glasses and thermal dilatation was measured and used to calculate the reference viscosity points. The results illustrate the complexity of historical glass melting, as well as the technological progress between different periods.

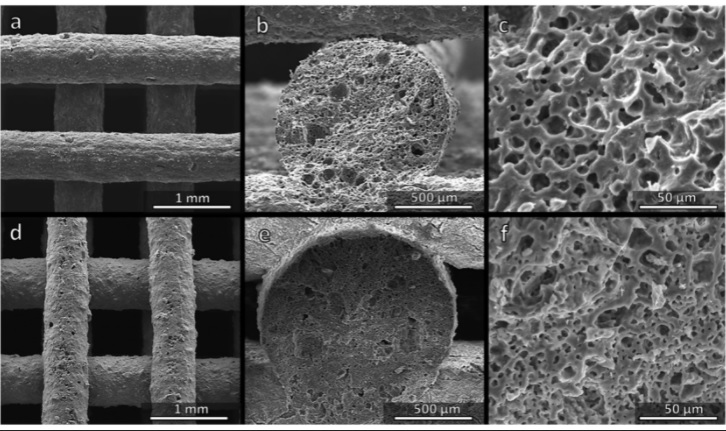

![]() Dogrul, F.; Ożóg, P.; Michálek, M.; Elsayed, H.; Galusek, D.; Liverani, L.; Boccaccini, A.R.; Bernardo, E.: Polymer-Derived Biosilicate®-like Glass-Ceramics: Engineering of Formulations and Additive Manufacturing of Three-Dimensional Scaffolds. In: Materials 2021, 14, 5170.

Dogrul, F.; Ożóg, P.; Michálek, M.; Elsayed, H.; Galusek, D.; Liverani, L.; Boccaccini, A.R.; Bernardo, E.: Polymer-Derived Biosilicate®-like Glass-Ceramics: Engineering of Formulations and Additive Manufacturing of Three-Dimensional Scaffolds. In: Materials 2021, 14, 5170.

https://doi.org/10.3390/ma14185170

Abstract: Silicone resins, filled with phosphates and other oxide fillers, yield upon firing in air at 1100 °C, a product resembling Biosilicate® glass-ceramics, one of the most promising systems for tissue engineering applications. The process requires no preliminary synthesis of parent glass, and the polymer route enables the application of direct ink writing (DIW) of silicone-based mixtures, for the manufacturing of reticulated scaffolds at room temperature. The thermal treatment is later applied for the conversion into ceramic scaffolds. The present paper further elucidates the flexibility of the approach. Changes in the reference silicone and firing atmosphere (from air to nitrogen) were studied to obtain functional composite biomaterials featuring a carbon phase embedded in a Biosilicate®-like matrix. The microstructure was further modified either through a controlled gas release at a low temperature, or by the revision of the adopted additive manufacturing technology (from DIW to digital light processing).

Afsharimani, N, Talimian, A, Merino, E, Durán, A, Castro, Y, Galusek, D.: Improving corrosion protection of Mg alloys (AZ31B) using graphene-based hybrid coatings. In: International Journal of Applied Glass Science. 2021; 1– 8.

https://doi.org/10.1111/ijag.16539

Abstract: In the present work, a study was carried out to compare the morphology and electrochemical properties of pure and graphene-modified hybrid silica sol–gel coatings deposited on anodized AZ31B magnesium alloys. The precursor solution was prepared using tetraethoxysilane (TEOS) and 3-glycidoxypropyl-trimethoxysilane (GPTMS), with the addition of chemically modified graphene nanosheets (GN-chem). Homogeneous and adherent coatings were obtained using GPTMS-TEOS (GT) and GPTMS-TEOS-GN-chem (GT/GN-chem) solutions with uniform thickness around 4 µm. Raman, SEM images and EDS analyses confirmed the presence of graphene nanosheets in the coatings. Potentiodynamic polarization results using 0.05 M NaCl electrolyte solution showed that graphene containing silica coatings significantly improve the corrosion resistance of AZ31B alloys. In addition, a significant passive region was observed for GT/GN-chem coatings.