New articles published by FunGlass in February:

González-Rodríguez, J.; Fernández, L.; Vargas-Osorio, Z.; Vázquez-Vázquez, C.; Piñeiro, Y.; Rivas, J.; Feijoo, G.; Moreira, M.T.: Reusable Fe3O4/SBA15 Nanocomposite as an Efficient Photo-Fenton Catalyst for the Removal of Sulfamethoxazole and Orange II. In: Nanomaterials 2021, 11, 533.

González-Rodríguez, J.; Fernández, L.; Vargas-Osorio, Z.; Vázquez-Vázquez, C.; Piñeiro, Y.; Rivas, J.; Feijoo, G.; Moreira, M.T.: Reusable Fe3O4/SBA15 Nanocomposite as an Efficient Photo-Fenton Catalyst for the Removal of Sulfamethoxazole and Orange II. In: Nanomaterials 2021, 11, 533.

https://doi.org/10.3390/nano11020533

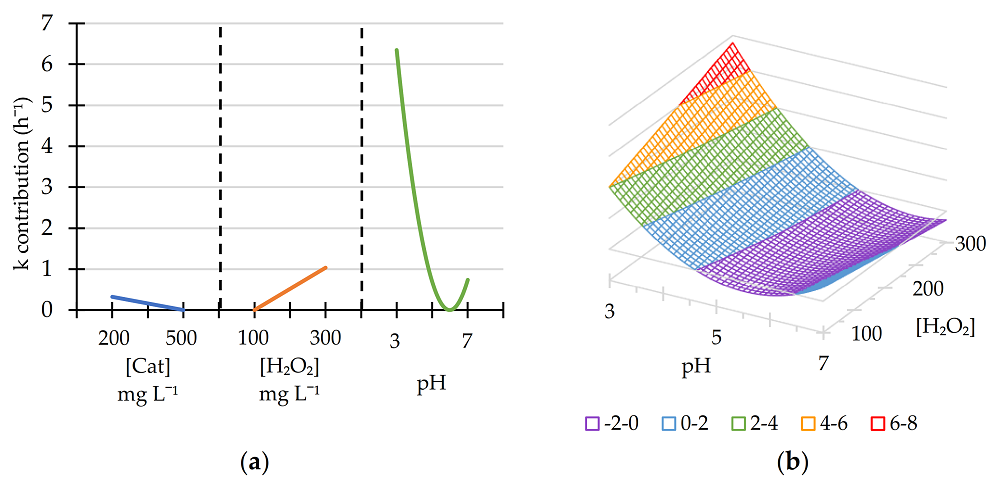

Abstract: Today, the presence of recalcitrant pollutants in wastewater, such as pharmaceuticals or other organic compounds, is one of the main obstacles to the widespread implementation of water reuse. In this context, the development of innovative processes for their removal becomes necessary to guarantee effluent quality. This work presents the potentiality of magnetic nanoparticles immobilized on SBA-15 mesoporous silica as Fenton and photo-Fenton catalysts under visible light irradiation. The influence of the characteristics of the compounds and nanoparticles on the removal yield was investigated. Once the key aspects of the reaction mechanism were analyzed, to evaluate the feasibility of this process, an azo dye (Orange II) and an antibiotic (sulfamethoxazole) were selected as main target compounds. The concentration of Orange II decreased below the detection limit after two hours of reaction, with mineralization values of 60%. In addition, repeated sequential experiments revealed the recoverability and stability of the nanoparticles in a small-scale reactor. The benchmarking of the obtained results showed a significant improvement of the process using visible light in terms of kinetic performance, comparing the results to the Fenton process conducted at dark. Reusability, yield and easy separation of the catalyst are its main advantages for the industrial application of this process.

G. Taveri, O. Hanzel, J. Sedláček, J. Toušek, Z. Neščaková, M. Michálek, I. Dlouhý, M. Hnatko: Consolidation of Bioglass® 45S5 suspension through cold isostatic pressing, Ceramics International, Volume 47, Issue 3, 2021, Pages 4090-4096.

G. Taveri, O. Hanzel, J. Sedláček, J. Toušek, Z. Neščaková, M. Michálek, I. Dlouhý, M. Hnatko: Consolidation of Bioglass® 45S5 suspension through cold isostatic pressing, Ceramics International, Volume 47, Issue 3, 2021, Pages 4090-4096.

https://doi.org/10.1016/j.ceramint.2020.09.283

Abstract: A new procedure for Bioglass® 45S5 powder consolidation was carried out in two water-based solutions using isostatic pressure. Nearly fully dense samples were obtained by precipitation of a dissolution product from Bioglass® powder mixed with distilled water or 1 M NaOH solution. The microstructure of the processed samples was inspected through SEM observations and the chemistry of the base material and the dissolution product was analyzed by EDX, Raman, and NMR spectroscopies. The base material and the precipitate differ in chemical nature, as evidenced by differences in chemical shifts in the NMR and Raman spectra, while the EDX line-scan showed a compositional gradient of the Bioglass® sample processed in NaOH. The immersion of the densified samples into the simulated body fluid (SBF) exhibited hydroxyapatite formation even after one day. The newly densified Bioglass® 45S5 could open up a new perspective in its practical exploitation in bio-engineering applications.

A. H. Pakseresht, S. M. Mousavi, M. Saremi, E. Ghasali & H. Rajaei: Microstructure and mechanical properties of YSZ-alumina composites designed for thermal barrier coatings. In: Materials at High Temperatures, Vol. 38, Issue 1, p. 23-30

A. H. Pakseresht, S. M. Mousavi, M. Saremi, E. Ghasali & H. Rajaei: Microstructure and mechanical properties of YSZ-alumina composites designed for thermal barrier coatings. In: Materials at High Temperatures, Vol. 38, Issue 1, p. 23-30

doi/full/10.1080/09603409.2020.1837414

Abstract: Over the last years, there has been a growing number of studies on YSZ-alumina coatings relevant to the field of thermal barrier coatings. These coatings, either in the form of whiskers or particles reinforced, have been shown to have better properties in comparison to conventional counterparts. Apart from other aspects related to coatings, it is interesting to pose the question: is there any interaction between YSZ and alumina particles which would lead to the amelioration of the properties? Therefore, this study was launched to address the microstructural and mechanical features of YSZ-alumina composites. Since examination and detection of the phases that might be formed in the YSZ-alumina binary system would be a difficult task if the samples had been prepared by the common techniques for the coating preparation, Spark Plasma Sintering was employed to achieve dense samples to find a correlation between the microstructure and mechanical properties.

F. Sharifianjazi, A. Esmaeilkhanian, M. Moradi, A. H. Pakseresht, M. S. Asl, H. Karimi-Maleh, H. W. Jang, M. Shokouhimehr, R. S. Varma: Biocompatibility and mechanical properties of pigeon bone waste extrac ted natural nano-hydroxyapatite for bone tissue engineering. In: Materials Science and Engineering: B, Volume 264, 2021, 114950.

F. Sharifianjazi, A. Esmaeilkhanian, M. Moradi, A. H. Pakseresht, M. S. Asl, H. Karimi-Maleh, H. W. Jang, M. Shokouhimehr, R. S. Varma: Biocompatibility and mechanical properties of pigeon bone waste extrac ted natural nano-hydroxyapatite for bone tissue engineering. In: Materials Science and Engineering: B, Volume 264, 2021, 114950.

https://doi.org/10.1016/j.mseb.2020.114950

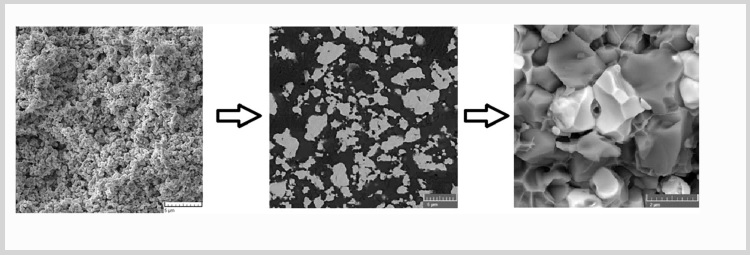

Abstract: One of the common bioactive materials used for clinical and biomedical applications is hydroxyapatite (HAp). Bio-waste materials are one of the major natural sources for the preparation of this bio-ceramic powder. Herein, naturally derived nano-HAp was prepared using the ball milling process after annealing of waste pigeon bones at 850 °C followed by cold-pressing the nanoparticles and re-sintering at 850, 950, 1050, and 1150 °C. The ball-milled pigeon-derived nano-hydroxyapatite (PHA) had an average particle size in the range of 50–250 nm and the Ca/P ratio of the sample sintered at 1050 °C was 1.7. Moreover, the hardness and compressive strength of sintered nano-HAp were improved to 47.57 MPa and 3.7 GPa, respectively by increasing the sintering temperature. Furthermore, alkaline phosphatase analysis and MTT assay of PHA indicated significant enhancement in the activity and proliferation of osteoblast cells during the culturing period in comparison to synthetic HAp.

A. Najafzadehkhoee, A. Habibolahzadeh, F. Qods, M. Vakhshouri, W. Polkowski, P. Hvizdos, D. Galusek: Effect of ZrC nanopowder addition in WC preforms on microstructure and properties of W–ZrC composites prepared by the displacive compensation of porosity (DCP) method. In: Journal of Australian Ceramic Society (2021)

A. Najafzadehkhoee, A. Habibolahzadeh, F. Qods, M. Vakhshouri, W. Polkowski, P. Hvizdos, D. Galusek: Effect of ZrC nanopowder addition in WC preforms on microstructure and properties of W–ZrC composites prepared by the displacive compensation of porosity (DCP) method. In: Journal of Australian Ceramic Society (2021)

https://doi.org/10.1007/s41779-020-00538-1

Abstract: In the present work, WC preforms with varied amounts of ZrC nanopowder (0–3.5 vol.%) were prepared using gel-casting base on nontoxic sodium alginate and then reactively infiltrated by molten Zr2Cu through displacive compensation of porosity method. The influence of ZrC nanopowder addition on the relative density, phase composition, microstructure, and properties of the final composites were investigated. The relative density, Vickers hardness, and flexural strength of the resulted composites prepared by reactive infiltration first increased and then decreased with increasing fraction of ZrC nanopowder in WC preforms. When the added fraction of ZrC nanopowder was 1.5 vol.%, the relative density, hardness, and flexural strength of the resulted composite reached their maximum values of about 97.3± 1%, 10.9± 0.3 GPa, and 503± 3 MPa, respectively. Fractography studies revealed that the fracture mode of composites was predominately intergranular. The W-ZrC composite was ablated by an oxyacetylene flame for 60 s. The mean value of mass and linear ablation rates of the composite were 2.1 ± 0.1 mg/s and 2.9 ± 0.3 μm/s, respectively. W-ZrC composites fabricated in complex and near net shapes at modest temperature and at ambient pressure by a reactive infiltration process can be utilized in aerospace applications.

M. Michálková, J. Kraxner, M. Parchovianský, R. Klement, V. Pouchlý, K. Maca, D. Galusek: Viscous flow spark plasma sintering of glass microspheres with YAG composition and high tendency to crystallization. In: Journal of the European Ceramic Society, Volume 41, Issue 2, 2021, Pages 1537-1542.

M. Michálková, J. Kraxner, M. Parchovianský, R. Klement, V. Pouchlý, K. Maca, D. Galusek: Viscous flow spark plasma sintering of glass microspheres with YAG composition and high tendency to crystallization. In: Journal of the European Ceramic Society, Volume 41, Issue 2, 2021, Pages 1537-1542.

https://doi.org/10.1016/j.jeurceramsoc.2020.10.015

Abstract: Present work is focused on the preparation of bulk glass with stoichiometric yttrium aluminium garnet (YAG) composition, which has high tendency to crystallize. Glass microspheres were prepared by flame synthesis from sol-gel prepared YAG precursor. Sintering conditions in SPS apparatus such as heating rate, pressure and temperature were optimized with the aim to prepare transparent material. Results revealed that glass with high tendency to crystallize is very sensitive to time of densification under load (associated with the maximum applied temperature). The increase of the pressure led to the expansion of the translucent part of the sample. Dense, and slightly translucent amorphous samples (total transmission measured at 550 nm was 4.8 %) were successfully prepared by viscous flow SPS sintering of glass microspheres at temperatures below 910 °C without any isothermal dwell.